Basic Member

Get a free quote or proposal for

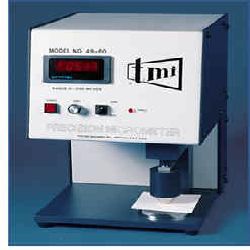

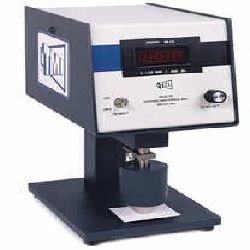

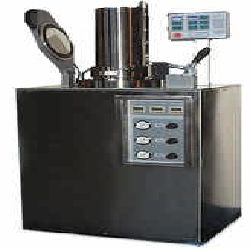

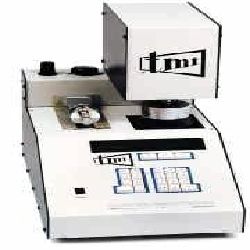

Burst Tester (Paper, Film, Foil)

DESCRIPTION: |

|

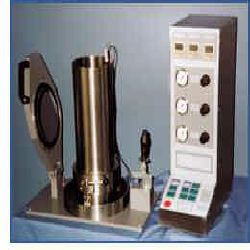

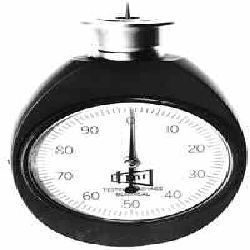

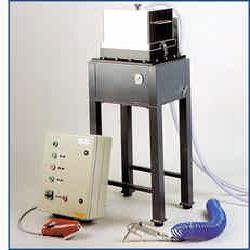

INTRODUCTION: Burst Testers are used as multi-directional tensile test to identify failure in the direction of least resistance for evaluating the materials physical strength and fiber bond. Models are available to test a variety of materials. These models can also be fitted with a device to measure the deflection of the sample prior to burst. PRINCIPLE: The Burst Tester is designed for measuring the bursting strength of sheet materials subjected to an increasing hydrostatic pressure. This pressure is applied to a circular region of the specimen via an elastic diaphragm. The specimen is firmly held round the edge of this circular region by a pneumatic clamping device. When the pressure is applied, the specimen deforms together with the diaphragm. The bursting strength corresponds to the maximum pressure supported by the specimen before failure. Identical, in the principle to a multi-directional tensile test, this measurement is independent from the cutting direction of the sample (machine or cross) since the failure naturally occurs in the least resistance direction. The rubber diaphragms with specific thickness and shore hardness must have a bulge versus pressure pattern within the tolerance of the standards related to the type of material tested. APPLICATIONS: Paper, Corrugated SPECIFICATIONS: * Paper and Foil Standards- ISO 2758 * Corrugated- ISO 2759 * Textile Standards- NF G.07112, ASTM D 774 FEATURES: * Menus allow programming to meet pre-defined test methods and international standards * Pneumatic sample clamping * Large graphic LCD * The tightness pressure is measured with a pressure transducer and displayed in bar/PSI * Software to transfer data to Excel: Testlink3 * Date of last calibration stored in memory (clamp pressure, bursting pressure, and height gauge) * Number of test performed with diaphragm stored in memory * Date of diaphragm replacement stored in memory * Safety : One start button when safety hood covers the test area and two start buttons, which has to be pushed simultaneously when cover is up to have a better view on the test area. * Option : Height gauge to measure the height for the Burst * Option : printer, small sized and handy roll printer delivers 40 column tickets. Exists with a serial port for direct connection to the burst tester or with a centronics port for PC operations. |

|

COMMERCIAL DETAILS: |

|

| FOB Price * | Not Mentioned |

| Payment Terms | As mutually agreed |

MORE DETAILS: |

|

| Sample Offered? | Not Applicable |

| Sample Terms | Not Applicable. |

| * Prices are subject to change. Please contact the supplier for the latest price. | |

Veronica Felix

Executive, Testing Machines Inc.

Member Since: Aug 2007

Location ![]()

| Address Line1 | 40 McCullough Drive |

| City | New Castle |

| Postal Code | 19720 |

| State | Delaware |

| Country | United States |

| Region | North America |

Office Schedule

| Working Days | Monday to Friday |

| Working Hours | 9 AM to 5 PM |

- This profile was recently viewed by visitors from Japan, United States, Canada, Germany, Ireland.

Product Listings

by Testing Machines Inc.

Similar Products from Suppliers in Other Countries

Bursting Strength Tester

The Bursting Strength Tester- Digital is the instrument that is mainly used in paper and packaging industries as well as the textile industries for ensuring the best quality of the packaging...

Digital Bursting Strength Tester

This equipment determines the bursting strength of corrugated fiber board & paperboard. The bursting pressure, at the time of rupture is recorded on the digital display panel as well as on the...

Burst Tester

Measuring range: 10~2000kpa Clamping force between upper and lower chucks >430 kpa Pressure delivery speed: 95±5ml/ min Film resistance Strike height 10mm,20-40 kpa Machine accuracy: 1 level...

Digital Burst Strength Tester

Bursting Strength is a reliable index of the strength and performance of materials like paper, paperboards, corrugated boards, and boxes, etc. Bursting Strength Tester is ideal for testing a wide...

Bursting Strength Tester / Crush Tester

Bursting Strength is a reliable index of the strength and performance of materials like paper, paperboard, corrugated boards and boxes, solid fibreboard, filter cloth, industrial fabrics, leather,...

Bursting Strength Tester

Bursting strength tester is useful to determine BS (bursting strength), BF (bursting factor) of paper, paperboard, corrugated box and other similar products .

Burst strength tester

The tester is the basic instrument for testing the anti-bursting degree of paper and cardboard. It conforms to the standards of ISO2758 Paper- Determination of bursting strength, ISO2759 Board-...

Burst Tester

The burst test device is an accessory for testing machines. It takes over the function of the hydraulic pump and does the data acquisition and evaluation.

Paper Testing Equipment

Complete testing solutions for mechanical testing of paper products and materials. Digital technology and the worlds leading testing software offers major benefits to paper testing laboratories....

Find More Products in These Categories

More Product Listings

Looking for Buyers Instead?

Burst Testers Buyers from around the world