Basic Member

Get a free quote or proposal for

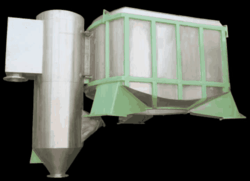

Trommel Screen

DESCRIPTION: |

|

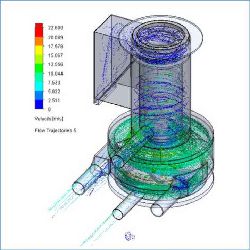

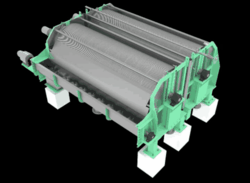

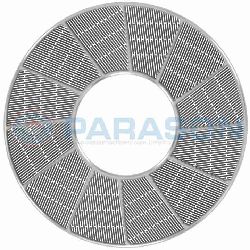

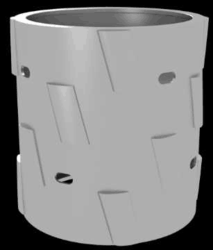

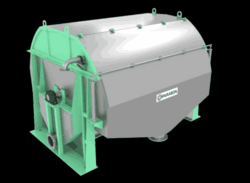

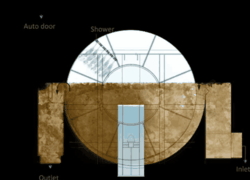

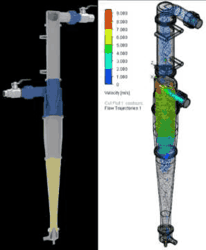

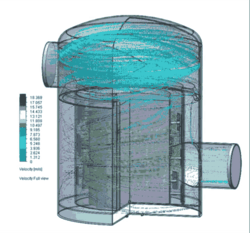

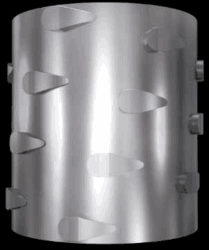

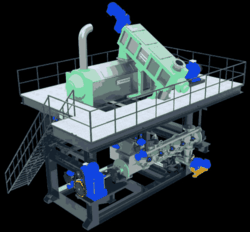

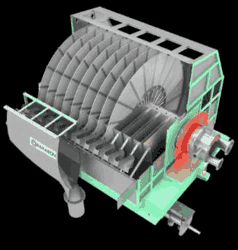

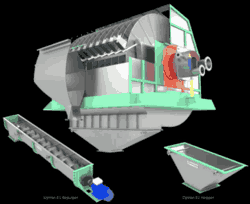

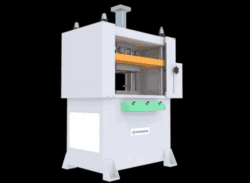

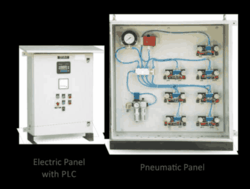

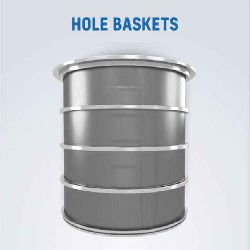

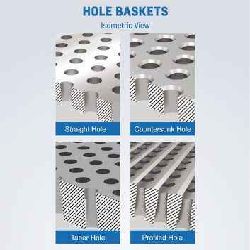

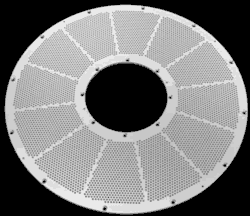

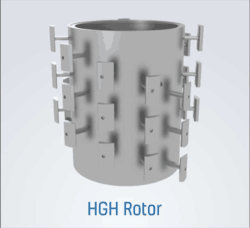

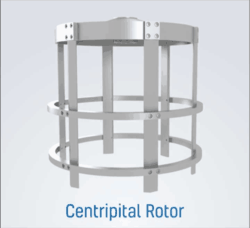

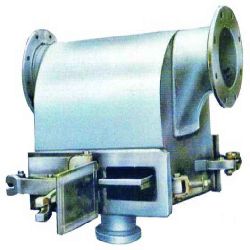

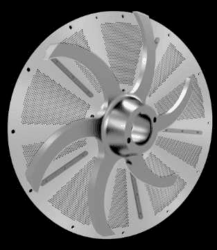

Parason produces the most durable and efficient Trommel screens in the pulp & paper industry. Using a revolving screened cylinder to accomplish the separation of material by size, our trommel screens are ideal for construction and demolition waste, municipal solid waste, green waste, and waste to energy front-end separation systems. Our Trommel screens are positioned at the beginning of the equipment line, replacing the need for multiple pieces of equipment. All our Trommel screens are engineered with an energy-efficient design that utilizes gravity and centrifugal force to separate different material sizes from the waste stream. Special Features: Easy Installation The perforated drum of SS-304, drive arrangement, inside helical screw, outlet chute of SS-304, and supporting structure of M.S. The drum is driven through a geared motor, pulleys, and belts C-I drive and driven pulleys properly machined Shower pipe with nozzles of SS-304 Applications: For separating fibers and large coarse contaminants from the recycled fiber pulp after the pulper Special heavy-duty perforated drum allowing the recovery of fibers and rejecting the coarse contaminants accepts returned to the pulper Works as a secondary coarse screen and installed in pulper reject/accept line depending on the type of pulper & contaminants Working Principles - The Trommel is a rotating perforated drum. Contaminants and fibers fed into the Trommel screen from one end. To increase fiber recovery, the Trommel is slowly rotated to agitate the stock, water is added through shower provided to aid the fiber/ contaminants separation. Large contaminants are rejected from the system as the helical screws welded inside the drum, force them out from the other end of the Trommel. The suitable hole size of the perforated drum is selected to optimize the separation properties and fiber recovery qualities. The accept from the Trommel containing fiber, water, and small contaminants collected in the tray by gravity and feed back to the pulper. Specification/Additional Details: Usage/Application - Industrial Capacity - 8 to 40 TPD Motor Power - 3.7 to 11 kW Automation Grade - Automatic Applications - To lessen the contaminant load on fiber saver (PFS), the light rejects normally directed to Trommel |

|

COMMERCIAL DETAILS: |

|

| Avg. Lead Time | 1 Day |

| FOB Price * | Not Mentioned |

| Payment Options | L/C, T/T |

| Country of Origin | Aurangabad, Maharashtra, India |

MORE DETAILS: |

|

| Product Condition | New |

| Brand Name | Parason |

| Sample Offered? | Not Applicable |

| * Prices are subject to change. Please contact the supplier for the latest price. | |

Vijay S

Member Since: Jun 2019

Location ![]()

| Address Line1 | 4th Floor, Golden Dreams IT Park, E-27 |

| Address Line2 | Chikalthana MIDC, Beside Millennium Park, Near Prozone Mall |

| City | Aurangabad |

| Postal Code | 431005 |

| District / County | Aurangabad |

| State | Maharashtra |

| Country | India |

| Region | South Asia |

- This profile was recently viewed by visitors from Nigeria, India, Germany, United States, Canada.

Product Listings

by Parason Machinery India Pvt Ltd

Similar Products from Other Suppliers in Aurangabad

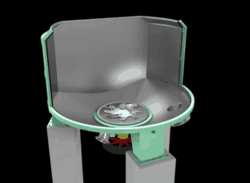

Parason Low Consistency Secondary Screen

Vertical pressure screen with periodic reject discharge as secondary screen in stock preparation as well as approved flow section. PARASON PRESSURE SCREEN OFFERS: *Exceptional improvement in...

Parason Machinery (India) Pvt Ltd. Aurangabad, Maharashtra, India

Multi Screen

Our Multi Screen has the following features: *Coarse Screening, Primary Fine Screening operation in one Screen. *H+S Hole & Slot in one screen only. *Excellent Screening performance with low...

Parason Machinery (India) Pvt Ltd. Aurangabad, Maharashtra, India

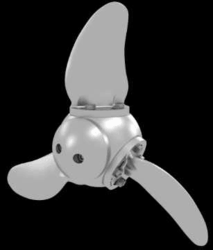

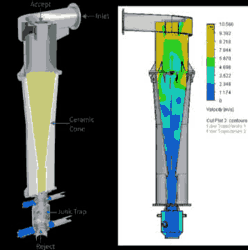

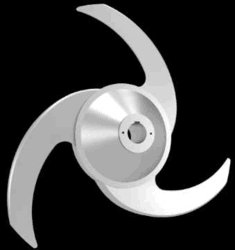

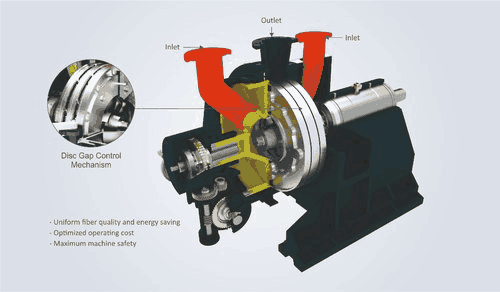

Parason Turbo Separator

APPLICATION: Parason Turbo Separator is a disc screen specially designed for coarse screening of primarily for Pulp strainer with a high trash and flake consent like recycled paper. WORKING...

Parason Machinery (India) Pvt Ltd. Aurangabad, Maharashtra, India

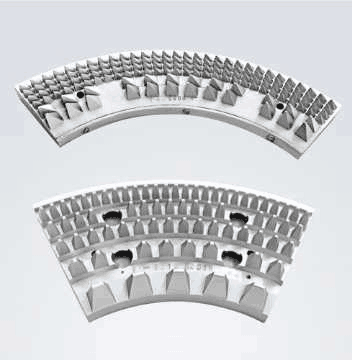

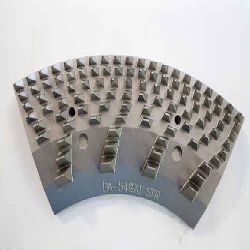

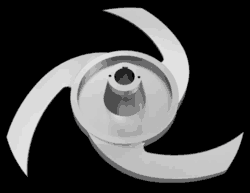

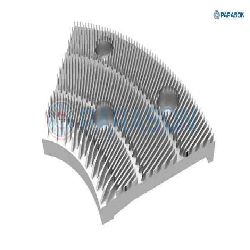

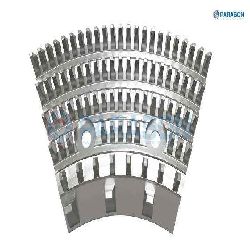

Screen Baskets

A key component in the Pulp and Paper technology process. Profile Bar type slotted basket has high open area for efficient screening. Made on CNC machines with/without profile. Excellent efficiency.

Parason Machinery (India) Pvt Ltd. Aurangabad, Maharashtra, India

Parason Low Consistency Screen

Vertical screen designed for fine screening of all kind of stock suspensions at low consistency range of 0.4-1.1%. The screens are suitable for stock preparation system and also for approach flow...

Parason Machinery (India) Pvt Ltd. Aurangabad, Maharashtra, India

Parason Reject Screens

Useful for handling reject of the primary screens and excellent separation of contaminants without fiber loss. Please send us your inquiry to buy reject screens.

Parason Machinery (India) Pvt Ltd. Aurangabad, Maharashtra, India

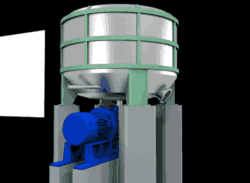

Parason Trommel Screen

Parason Trommel Screen: Excellent fiber recovery from pulping section. Please contact us for product specs and pricing information.

Parason Machinery (India) Pvt Ltd. Aurangabad, Maharashtra, India

Parason Medium Consistency Screen

The ideal screen for waste paper stock preparation (white and brown grade). The special rotor design allows the screen to operate at 3-5.5% consistency. The stock suspension is screened through a...

Parason Machinery (India) Pvt Ltd. Aurangabad, Maharashtra, India

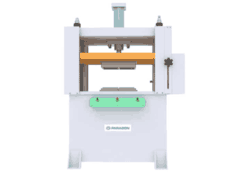

Horizontal Pressure Screen

APPLICATION : Parason Horizontal screen is designed for coarse screening at Pulp mill/Stock preparation stage and to work with waste paper/mill pulp. WORKING PRINCIPLE: Pulp stock at 2 to 4 %...

Parason Machinery (India) Pvt Ltd. Aurangabad, Maharashtra, India

Parason Screen Baskets

Paperason Screen baskets are a key component in the pulp & paper technology process. *Latest in Screening Technology *PARASON PROFILE WEDGE BAR BASKETS (SLOTTED) *Profile wedge bar basket is a...

Parason Machinery (India) Pvt Ltd. Aurangabad, Maharashtra, India

Similar Products from Companies in Rest of India

Low Consistency Secondary Screens

Salient Features * Vertical pressure screen with periodic reject discharge as secondary screen in stock preparation as well as approach flow section * Exceptional improvement in screening *...

JMC Engineers Ahmedabad, Gujarat, India

Vibratory Screens

Vibration Screens are used for screening of all fibers containing impurities. These screens are used for screening of low as well as high consistency pulp. The screen removes large impurities such...

JMC Engineers Ahmedabad, Gujarat, India

Medium Consistency Screens (MC)

The ideal screen for waste paper stock preparation (white and brown grade). The special rotor design allows the screen to operate at 3 -4.5% consistency. The stock suspension is screened through a...

JMC Engineers Ahmedabad, Gujarat, India

Low Consistency Screens

Salient Features: * Vertical screen designed for fine screening of all kind of stock suspensions at low consistency range of 0.4 -1.1%. * The screens are suitable for stock preparation system and...

JMC Engineers Ahmedabad, Gujarat, India

Pressure Screen

Pressure screen for all final screening of stock in capacities upto 100 T.P.D. The Screen are easy to operate, mantain and are non-colgging type.

Orien Paper Machinery Pvt. Ltd. Ghaziabad, Uttar Pradesh, India

Similar Products from Suppliers in Other Countries

Vibrating Screen

Vibrating Screen for stock preparation A vibrating screen is used for the removal of various impurities in pulp suspension. When the cleaner working, the stock is run to the bottom of the gas seal...

MC Pressure Screen

MC pressure screen Applicable process: Best for the hot screening of wood or straw pulp after cooking and before washing. It also can be used for coarse screening to groundwood pulp and MC...

Outflow Pressure Screen

Outflow pressure screen Applicable process: Used for fine or coarse screening to waste stock Size:0.3-4m2 Inlet consistency:0.8-3% Production capacity: 10-500T/D Choose different rotor and...

Inflow Pressure Screen

Inflow pressure screen Applicable process: For fine screening of stock and stock flow approach. Size:0.8-6m2 Inlet consistency:0.5-1.2% Production capacity:20-780T/D Stock supply operation...

Knot Screens

Knot Screen Applicable process: Removes knots, grass festival?metal or sand and so on which contains in the stock that after cooking. Size:0.4-3m2 Inlet consistency:1.0-5.0% Production capacity:...

Screen Baskets

All kinds of screen baskets like milled baskets, perforated baskets and wedge wire baskets and so on according to your specific request, please contact for more information

Out-Flow Type Pressure Screen

For coarse screen and fine screening of pulp screen system High quality filtered pulp Prevent plug screen plate Low power consumption High capacity Low reject rate for small reject equipment High...

Stainless Steel Wire Mesh

Stainless Steel Wire Mesh Application of stainless steel wire mesh: Stainless steel wire mesh products, woven with stainless steel wire(SUS304M; are acid-resisting, soda-resisting and...

Pressure Screen

Stainless steel for all surfaces in contact with pulp, durable and corrosion resistant. Stock inlet equipped with pressure gauge. Removable top cap for easy cleaning and maintenance. Optional...

Paper Machine Clothing

We are a specialized manufacturer and exporter for polyester fabric in China. Our polyester fabrics are divided into polyester forming fabric, polyester spiral dryer fabric, polyester dryer fabric,...

Find More Products in These Categories

More Product Listings

Looking for Buyers Instead?

Screens Buyers from around the world

.png)