📌 Key Takeaways

Grease resistance in food wrapping paper comes down to one number—the Kit level (1–12)—not paper thickness or weight.

- Kit Level Measures Oil Resistance, Not Thickness: A thin paper with strong barrier chemistry can outperform a heavy paper with weak grease resistance.

- Match Kit Level to Fat Content and Hold Time: Dry bread needs Kit 1–4, burgers need Kit 5–7, and fried foods like wings need Kit 7–9.

- Folds and Creases Create Weak Spots: Paper rated Kit 8 on a flat sample may perform closer to Kit 5 where the coating cracks at sharp folds.

- Always Request TAPPI T 559 Test Results: Ask suppliers for the specific Kit level rating, not just a vague “grease-resistant” claim.

- Test Before Bulk Orders: Run a stress test—wrap your product, hold it under heat lamps at peak times, and check for oil strike-through.

Right Kit level = clean hands and crisp food

wrong Kit level = soggy mess and customer complaints

Food service operators and food packaging paper buyers will gain clarity on specifying grease-resistant paper, preparing them for the detailed cheat sheet and supplier checklist that follow.

~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~

Hot wings hit the wrapper. Oil seeps through in seconds. The bag bottom spots, and the customer’s hands come away slick.

That’s not a paper problem. That’s a spec mismatch.

The difference between greasy mess and clean presentation comes down to one number most operators never ask about: the kit level. This guide gives you a practical reference for matching kit levels to your menu—so you can spec with confidence and stop guessing.

What Kit Levels Measure (and What They Don’t)

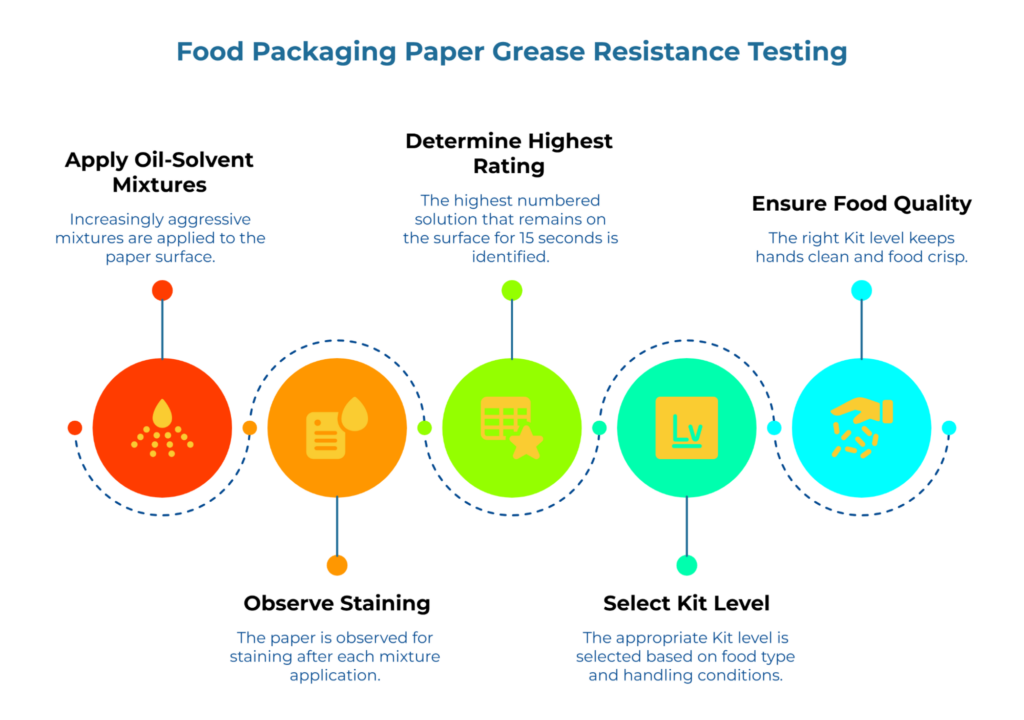

Grease resistance is not the same thing as thickness. In food wrapping paper, grease resistance is a performance property that determines whether oil and fat will penetrate the sheet over time. A low-GSM paper can perform well if it has strong grease resistance, and a heavy paper can still fail if the barrier is weak. This is why specs like Kit level (1–12) exist: they standardize grease resistance so buyers can select the right performance level based on the food type and handling conditions. For a kitchen manager, the practical outcome is simple: the right Kit level keeps hands clean and food crisp; the wrong one makes paper soggy, messy, and unreliable.

The kit test—standardized as TAPPI T 559—applies increasingly aggressive oil-solvent mixtures to the paper surface. The final rating is the highest numbered solution that remains on the surface for 15 seconds without staining. Higher numbers mean stronger grease shields.

What kit level does not tell you: heat resistance, wet strength, printability, or how the paper performs after folding. Those are separate specs entirely.

Kit Levels 1–12: Grease Resistance Cheat Sheet

Use this table as a starting point when specifying food packaging paper. Match the kit level to the fat content and expected hold time of your menu items.

| Kit Level | Grease Resistance | Typical Food Applications |

| 1 | Minimal | Dry bread, rolls |

| 2 | Minimal | Non-greasy baked goods |

| 3 | Low | Light pastries, plain cookies |

| 4 | Low | Lightly buttered items |

| 5 | Moderate | Standard sandwiches, wraps |

| 6 | Moderate | Burgers, pizza slices |

| 7 | Good | Fried chicken, doughnuts |

| 8 | Good | Fries, wings (standard hold time) |

| 9 | High | Heavy fried foods, extended hold |

| 10 | High | Oily sauces, long warming periods |

| 11 | Maximum | Specialty/industrial applications |

| 12 | Maximum | Extreme oil exposure scenarios |

These are starting points. When specifying for a new menu item, test with actual food before committing to bulk orders.

How to Pick a Kit Level for Common Foodsv

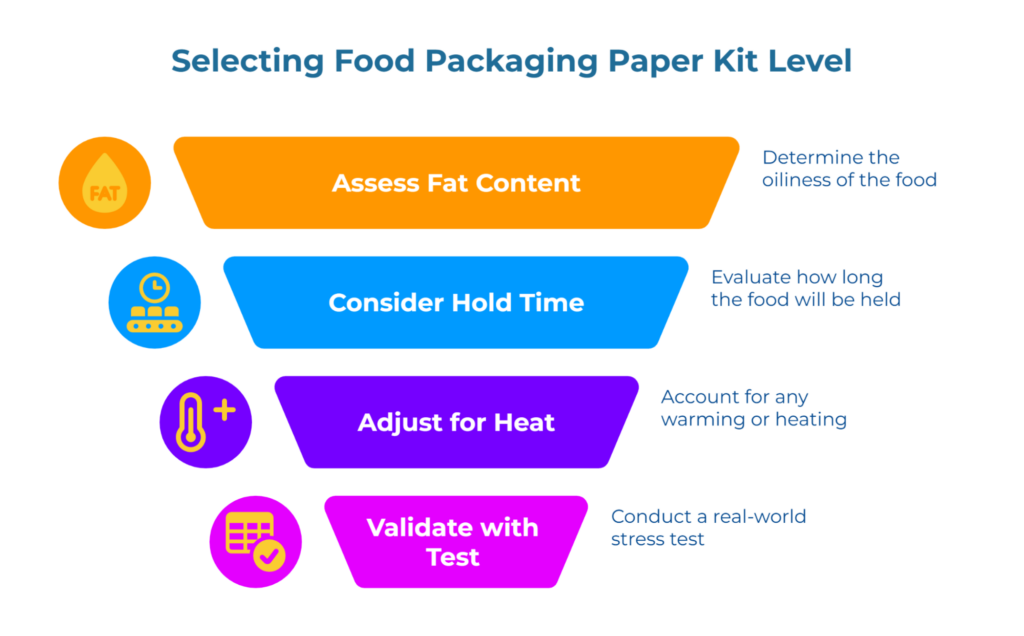

Start with fat content, then adjust for hold time and heat.

Low-fat and dry items such as bread, plain pastries, and cookies generally perform well with Kit 1–4. These foods release minimal oil, so a basic barrier is usually sufficient.

Moderate-fat items like sandwiches, standard burgers, and pizza slices typically need Kit 5–7. If food sits for 15–20 minutes before serving, lean toward the higher end of that range.

High-fat and fried items—wings, fries, fried chicken, doughnuts—usually require Kit 7–9. Longer hold times or especially oily recipes push the requirement toward 8 or 9.

Extreme oil exposure from heavily sauced items or extended warming periods may require Kit 10–12, though most food service operations rarely need this range.

Hold time matters more than many operators realize. A kit level that works for immediate service may fail when food sits in a warming drawer for 30 minutes.

Rule of thumb: Match to fat level and hold time, then validate with a real-world test. Over-specifying wastes money; under-specifying creates messy handling and customer complaints.

A simple operational check usually settles doubts: conduct a ‘Stress Test’: wrap the product, subject it to peak hold times under heat lamps, and inspect for strike-through. If the paper holds up under your actual conditions, you’ve found your spec.

How Kit Level Interacts with GSM, Coatings, and Folds

Many wrap failures happen not because the paper is “too thin,” but because the grease barrier rating is under-specified—or compromised at creases and folds.

Oil finds weak points. When paper is folded, scored, or converted (printed, laminated, die-cut), the grease barrier can break down at those stress points. A sheet rated Kit 8 on a flat sample may perform closer to Kit 5 at a sharp crease where the coating has cracked.

This is why understanding GSM and burst factor separately from kit level matters. GSM affects how paper handles folding—a heavier sheet may hold shape better—but it doesn’t compensate for weak barrier chemistry.

Coatings and treatments also affect performance. Some papers achieve high kit levels through chemical treatments; others use physical barriers. The coating type determines whether the barrier survives converting, printing, and real-world handling. When evaluating suppliers, ask how the kit rating holds up after the paper has been folded or processed—not just on a flat, untouched sample.

Common Mistakes When Ordering Grease-Resistant Paper

Confusing kit level with GSM. Ordering ‘heavier paper’ (higher GSM) when the problem is grease strike-through rarely solves the issue. GSM measures weight, whereas Kit Level measures chemical resistance. A heavy board with no barrier will soak up oil faster than a thin sheet of food grade kraft paper with a Kit 9 treatment. Specify the kit level you need, then choose a GSM that fits handling and presentation requirements.

Over-specifying for dry foods. Kit 12 paper offers no benefit for low-fat items. Match the spec to actual food requirements, or you’re paying for performance you don’t need—a common source of unnecessary spend.

Not asking for test methods and conditions. A supplier may describe paper as “grease-resistant” without specifying the kit level or test method. Ask for the TAPPI T 559 result, and confirm whether testing was performed on flat samples or after converting.

Ignoring converting and printing impacts. Flexo printing, lamination, and die-cutting can all affect barrier performance. If your paper will be printed or converted, ask how that process impacts the rated kit level.

Quick Spec Checklist to Send a Supplier

Copy and adapt this checklist when requesting quotes for food grade packaging paper:

- Intended food application: [e.g., fried chicken, burgers, pastries]

- Expected hold time before serving: [e.g., immediate, 15 min, 30+ min]

- Minimum kit level required: [e.g., Kit 7 per TAPPI T 559]

- Target GSM range: [e.g., 35–50 GSM]

- Converting/printing requirements: [e.g., flexo print, die-cut, pre-folded]

- Food contact documentation requested: Declaration of Conformity (DoC) or Certificate of Analysis (CoA) confirming compliance with FDA 21 CFR or applicable food contact regulations

- Verification: Request a Kit test report or CoA per production lot to ensure batch-to-batch consistency

Sending this level of detail upfront helps you get comparable quotes and reduces back-and-forth. For more on structuring supplier requests, see comparability before price.

Frequently Asked Questions

What does kit level mean on grease-resistant paper?

The Kit level (1–12) quantifies how well paper shields against oil. As the rating increases, the barrier becomes more resilient to aggressive fats, typically verified via the TAPPI T 559 test.

What is kit level 7 used for?

Kit level 7 provides good grease resistance suitable for fried foods like chicken, doughnuts, and similar items with moderate oil content and standard hold times.

Which kit level do I need for fries?

Standard fries usually align with Kit 7 or 8. However, if your kitchen uses high-heat peanut oils or maintains a 20-minute holding window, specify Kit 9 to prevent base-spotting.

Is higher GSM the same as better grease resistance?

No. GSM measures paper weight and affects stiffness, but does not determine grease resistance. A lighter paper with strong barrier chemistry can outperform a heavier paper with weak barrier chemistry.

Can I use the same paper for all menu items?

You can, but it’s usually not cost-effective. Dry items don’t need high kit levels, so using Kit 8 paper for bread wastes money. Match specs to actual food requirements.

Why does my paper fail at the folds?

Creases and folds create weak points where barrier coatings can crack or fiber structure is disrupted. Oil wicks through these weak spots faster than through flat surfaces.

What to Do Next

Low-commitment first step: Use the cheat sheet to set a minimum kit level and GSM range for one menu item, then request a sample that matches those specs. Browse food packaging paper listings on PaperIndex to compare options before your next order.

Higher-commitment action: When sourcing from new suppliers, find food packaging paper suppliers and request quotes against the exact specs your menu requires. Submitting a buying requirement with documented kit level and GSM keeps offers comparable.

For direct sourcing, connect with food packaging paper mills who can provide technical specifications and testing documentation for their products

Resources

- TAPPI T 559 (Kit Test) overview

- Practical kit test one-sheet (Applied Paper Technology)

- Grease resistance testing overview (Smithers)

- GSM and Burst Factor primer

Disclaimer:

This article is for educational purposes only.

Our Editorial Process:

Our expert team uses AI tools to help organize and structure our initial drafts. Every piece is then extensively rewritten, fact-checked, and enriched with first-hand insights and experiences by expert humans on our Insights Team to ensure accuracy and clarity.

About the PaperIndex Insights Team:

The PaperIndex Insights Team is our dedicated engine for synthesizing complex topics into clear, helpful guides. While our content is thoroughly reviewed for clarity and accuracy, it is for informational purposes and should not replace professional advice.