📌 Key Takeaways

Moisture windows protect your converting line better than chasing exact numbers ever will.

- Windows Beat Targets: A defined moisture range (minimum–target–maximum) delivers more stable converting performance than hitting one precise value, because process stability matters more than precision.

- Three Points Control Quality: Setting minimum, target, and maximum moisture boundaries—then enforcing them through ISO 186 sampling and ISO 287 testing—prevents curl, telescoping, and downstream waste before defects reach your line.

- Storage Practices Drive Results: Proper acclimatization time (24–48 hours), complete wrap removal, and warehouse RH control (45–55%) materially affect whether in-spec paper stays in-spec through converting.

- Evidence Ends Supplier Disputes: Sharing method IDs (ISO 186 for sampling, ISO 287 for moisture testing), lot numbers, and measured values with suppliers shortens resolution time and prevents future shipment issues.

- Drift Detection Prevents Rejections: Monitoring widening spreads between minimum and maximum readings within lots, plus tracking inline-versus-lab correlation, catches supplier process problems before they force line stoppages.

Professional buyers, converters, and supplier sales engineers will find the operational framework here, preparing them for the detailed moisture window implementation guidance that follows.

Targets shift. Windows hold.

A chilled reel leaves the shipping container and enters a humid warehouse. Hours later, the first slit lifts with a quiet crackle—moisture imbalance announcing itself before the line even starts. That sound represents money and time about to be lost.

Kraft converting runs best when incoming stock stays within a defined moisture window rather than hitting a single precise value. A moisture window establishes the minimum, target, and maximum moisture boundaries you agree upon with suppliers and your QA team. Material that stays in-range reduces curl, telescoping, and downstream waste. Chasing one “perfect” moisture number often fails because this is a process stability problem, not a precision-aim problem.

Three core assertions govern moisture window management: acceptable windows reduce curl/telescoping risk; storage and conditioning practices materially affect stability; consistency within range beats exact target precision for runnability. This article explains how buyers, converters, and supplier sales engineers can set, verify, and maintain these windows, providing a printable one-page checklist operational teams can apply immediately on the production floor.

A moisture window defines an agreed band of acceptable moisture content for kraft paper—minimum, target, and maximum values working together. Professional converters prioritize keeping reels and sheets within this band over hitting one exact value. In-range consistency improves runnability and lowers defects such as curl and telescoping, provided moisture is sampled per ISO 186 and tested per ISO 287, and stock is properly conditioned before use.

What Is a Moisture Window?

A moisture window defines what’s “good enough to run” rather than “exactly on target.” The window is wide enough to account for natural variation in fiber properties, climate exposure, and logistics handling, yet tight enough to protect converting performance.

In practice, this means establishing three reference points. The minimum boundary represents the moisture level below which paper becomes brittle and prone to cracking during handling. The target value reflects the supplier’s nominal specification, typically inherited from mill process-control setpoints. The maximum boundary marks the threshold above which excessive moisture causes curl, telescoping, and dimensional instability.

Most kraft grades perform reliably within a 2.5 to 3.5 percentage-point window. Exact boundaries depend on whether the grade contains virgin or recycled fiber, the basis weight, the specific end-use application, and regional climate factors affecting storage and converting environments.

Within-Range vs On-Target: What Stability Means for Runnability

Traditional moisture specifications listing only a target value—without defining acceptable deviation—create operational ambiguity. Suppliers optimize process control to hit that exact number rather than maintaining consistent performance across a workable range. Receiving teams lack clear criteria when material arrives at 7.2% instead of the 7.5% target.

A window-based specification solves this. When purchase orders state ‘acceptable moisture: 6.5–8.5%, target 7.5%,’ suppliers understand they have operational flexibility within that band. QA teams gain clear accept/reject criteria. Material measuring 6.8% and material at 8.2% both pass because they fall within the dimensional-stability envelope that converting equipment accommodates.

Converting lines tolerate modest variation when properly conditioned production environments maintain stable temperature and relative humidity. What disrupts operations are dramatic moisture shifts between deliveries. Receiving a reel at 6.0% one day and 9.5% the next forces repeated adjustment of tension, temperature, and feed settings. Consistent arrivals anywhere in the window produce smoother throughput and fewer defects than erratic deliveries that occasionally hit the bullseye but frequently miss the acceptable range entirely.

Moisture Window One-Pager: Print-Ready Reference Chart

Module: Definition

A moisture window is an acceptable range (not a single target) within which kraft paper maintains stable converting performance. Moisture window → affects → curl/telescoping risk. Storage/conditioning practices → affect → stability. Consistency within range beats chasing exact targets for runnability.

Module: Acceptance Window (min/target/max)

Illustrative example for general-purpose kraft grades:

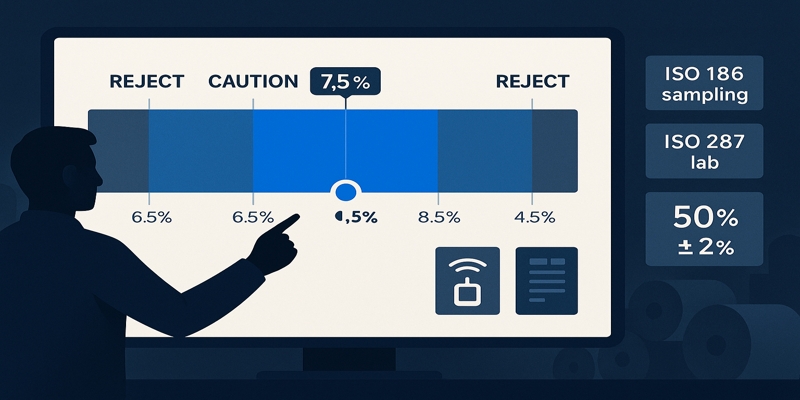

Visual Range-Band Chart:

REJECT | CAUTION | ACCEPT | CAUTION | REJECT

| | | |

<6.5% 6.5%–6.8% 6.8%–8.2% 8.2%–8.5% >8.5%

(min) (target 7.5%) (max)

- Minimum (lower boundary): 6.5% — below this, paper becomes brittle and prone to cracking

- Target (nominal center): 7.5% — supplier’s specification midpoint from mill process control

- Maximum (upper boundary): 8.5% — above this, excessive moisture causes curl, telescoping, and dimensional instability

Note: These are illustrative figures. Actual windows vary by grade (virgin vs. recycled), basis weight, and application. Use supplier lab data from recent shipments (3–6 months) to set your specific boundaries.

Module: Sampling & Measurement Basics

- Follow ISO 186 (sampling) for representative results. Sample minimum 3 reels per lot; take 3 points per reel (outer wrap, mid-depth, near core).

- For sheet stock: sample from top, middle, and bottom of stack across multiple pallets.

- Use inline meters for receiving checks; establish and maintain a correlation curve against the reference method. Verify quarterly against ISO 287 (oven-drying reference method).

- Document: date, lot number, measurement locations, ambient RH/temperature, pass/fail decision.

Module: Storage/Conditioning Checklist

☐ Acclimatization time: 24 hours minimum (standard reels <1,000mm), 48 hours (jumbo reels or heavy basis weights)

☐ Remove all protective wrapping completely before starting acclimatization clock—partial wrapping creates moisture imbalance

☐ Stage shipments in transition area if large temperature differential exists (cold container → warm warehouse)

☐ Target warehouse 50% ± 2% RH; log weekly trends with calibrated RH/temperature monitors in multiple zones. Focus on door lanes, corners, and upper racks where microclimates form.

☐ Seasonal protocols: high-RH months = faster stock rotation; low-RH months = prioritize equilibrated stock, shorten acclimatization. Reference TAPPI T 402 for standard conditioning atmospheres.

Module: Troubleshooting Flags

- Curl increase after first slits → check cross-web moisture uniformity; verify full acclimatization time completed

- Telescoping or starring on unwind → measure incoming moisture immediately; reject if exceeds upper boundary; inspect warehouse RH conditions

- Moisture spread (max–min) growing across samples → contact supplier for mill process-control review

- Inline sensors drifting from lab correlation → recalibrate and verify reference method alignment

- Supplier trending toward window boundary over time → request recent lab certificates; consider seasonal window adjustment

- Defects appear mid-run despite in-window moisture → investigate nip pressure, temperature settings, converting-room RH before attributing to paper

Print this chart and post it at receiving docks, QA labs, and production-floor entry points. Update the acceptance window values (min/target/max) based on your specific grades and supplier performance data.

The Failure Modes of Out-of-Window Stock

When kraft paper arrives outside its acceptable moisture window, specific and predictable defects emerge. Understanding these failure modes helps buyers and converters diagnose root causes quickly, while supplier sales engineers can use this knowledge to communicate proactively with customers and prevent claims.

Curl in Sheets

Sheet curl occurs when moisture content differs between the two sides of the paper, creating internal stress through differential dimensional change. This imbalance makes one side expand relative to the other. The sheet curves upward or downward depending on which side is wetter. The result: feeding jams in sheeting lines, poor registration in printing operations, and customer complaints about warped finished products.

Common causes include inadequate acclimatization after unwrapping (exposing only one face to air), uneven storage conditions where one side faces airflow while the other abuts a wall, and abrupt transitions from cold shipping containers into warm, humid warehouses that drive condensation onto outer layers. The corrective action isn’t necessarily rejecting material that measures 8.7% average moisture—it’s ensuring uniform moisture distribution across the web and from core to outer wrap through proper conditioning protocols.

Telescoping on Reels

Telescoping describes lateral misalignment of paper layers on a reel, creating a stepped or stair-like profile. The defect often appears alongside starring—radial separation patterns visible when viewing the reel end-on. Excessive moisture softens the paper and reduces caliper stability. During handling or storage, outer wraps slip relative to inner layers under the reel’s own weight, and wound-in stresses from the original winding become unstable.

Once telescoping begins, unwinding becomes difficult or impossible, and edge damage often propagates inward as operators attempt salvage. Risk increases when paper arrives at or above the upper window boundary and then sits in uncontrolled warehouse conditions for extended periods. Heavier basis weights and larger-diameter reels compound the problem through greater compressive force on softened layers.

Quick Audit Checklist

When curl or telescoping appears, work through this diagnostic sequence.

First, measure incoming moisture using a calibrated inline meter or lab test per ISO 287. Compare results against your defined window. Second, verify acclimatization time—confirm reels were unwrapped completely and allowed to equilibrate for the required period. Third, inspect the warehouse environment by reviewing RH and temperature logs; sudden RH spikes can drive moisture into exposed stock within 24–48 hours.

Fourth, request the supplier’s lab certificate showing moisture at time of shipment. If their result shows 7.9% but your incoming check reads 8.7%, moisture gain occurred in transit or storage. Fifth, review lot sampling notes for representativeness per ISO 186. Sixth, document evidence through photographs of defects, lot numbers, and moisture-meter readings to support claims discussions and help suppliers diagnose their process issues.

Setting Your Acceptance Window by Grade and Application

Generic moisture specifications fail to account for operational realities across different kraft grades and end-use applications. Heavy-basis-weight virgin kraft linerboard used in corrugated structures may require a narrower window because dimensional stability directly affects structural performance. Lightweight recycled kraft for inner plies or wrapping may operate reliably across a slightly wider range because precision demands are lower.

Using Supplier Specs and Lab Reports to Define Min/Target/Max

Begin with the supplier’s published technical data sheet and recent lab certificates. Most kraft paper specifications list a target moisture value—commonly 7.5% or 8.0%—sometimes noting a tolerance like ±1.0%. Treat this as an initial reference point rather than absolute truth.

Review lab certificates from the past three to six months to identify actual delivered values. If certificates consistently show results between 7.2% and 8.3%, that range reflects the mill’s true process capability rather than the aspirational target printed on data sheets. Build acceptance windows around observed performance, adding a modest buffer for seasonal variation and shipping-lane humidity exposure.

Illustrative example: A supplier’s spec sheet states ‘7.5% ± 1.0%,’ implying a 6.5–8.5% range. Lab certificates over six months show actual results of 7.1%, 7.4%, 7.8%, 7.6%, 8.0%, 7.5%, 7.7%, and 8.1%—an observed range of approximately 7.1–8.1%. An appropriate acceptance window might be 6.8–8.5%, accommodating minor variation while still rejecting material that drifts into the telescoping-risk zone above 8.5%.

Always verify the test method. ISO 287 is the international standard for measuring moisture content in paper and board. Confirming suppliers cite ISO 287 ensures comparability. If a supplier reports moisture using a different method or provides no method identification, request clarification before finalizing windows. If you need diversified supplier sources once your window is defined, you can find kraft paper suppliers through quality-focused marketplaces. For more guidance on test methods and lab report interpretation, explore the PaperIndex Academy.

When and How to Adjust the Window for Seasonality or Lane Humidity

Kraft paper equilibrates with ambient relative humidity during storage and transit. In tropical or monsoon-prone regions, material shipped during wet seasons may absorb moisture in-transit, arriving near the upper window boundary even if it left the mill within specification. Conversely, shipments moving through dry continental climates in winter may lose moisture, trending toward the lower boundary.

Rather than enforcing rigid windows year-round, consider seasonal adjustments based on shipping-lane climate data and receiving history. During humid-season months when regional RH exceeds 75%, narrow the upper boundary by 0.3–0.5 percentage points to account for expected moisture gain during warehouse acclimatization. In arid climates or winter conditions, lower the minimum boundary slightly, recognizing that material arriving at 6.3% can be conditioned back into the operational range through controlled humidification in storage areas.

Document seasonal adjustments in receiving procedures and communicate them to suppliers during contract negotiations. Suppliers appreciate transparency—it allows logistics teams to adjust packaging (additional wrapping for humid-season shipments) and production scheduling (shifting certain grades to dry-season manufacturing windows if tighter moisture control is needed). Strengthen wrap, limit airflow exposure, and avoid doorside storage to minimize transit-induced drift.

National meteorological agencies publish historical RH and temperature data for major shipping routes. Reviewing three to five years of seasonal averages supports evidence-based window setting rather than reactive adjustments after problematic shipments arrive. Resources like the World Meteorological Organization provide publicly accessible climate data. When verifying lots under controlled conditions, reference TAPPI T 402 for standard conditioning and testing atmospheres.

Storage, Acclimatization, and Conditioning Practices That Keep You In-Range

Even when kraft paper arrives within specification, improper storage or rushed conditioning can push it outside operational windows before reaching converting lines. Establishing consistent storage, acclimatization, and conditioning routines is as critical as setting the acceptance window itself. These practices prevent moisture-related defects and downstream waste.

Time-and-Temperature Acclimatization Rules of Thumb

Acclimatization means allowing incoming paper to equilibrate with warehouse temperature and humidity before unwrapping and feeding into production. Bring stock to the converting room’s conditions before processing. General guideline: 24 hours minimum for standard reels up to 1,000mm diameter, 48 hours for larger-diameter reels or heavier basis weights. These timeframes assume warehouses maintain stable conditions around 20–25°C and 45–55% RH.

Temperature differential matters significantly. If containers arrive after crossing cold ocean routes in winter and move directly into a 25°C warehouse, condensation forms on outer wraps, driving localized moisture spikes. Best practice: stage incoming shipments in a transition area where temperature gradually approaches warehouse levels over 12–24 hours, then complete full acclimatization in the main storage zone.

Pallet and Reel Wrapping Practices

Protective wrapping shields paper from moisture gain or loss during transit and storage, but it also slows equilibration once material arrives. Reels typically arrive wrapped in polyethylene film with edge protectors and often additional kraft-paper outer layers for abrasion resistance. Maintain intact moisture-barrier wrap until the moment of use.

When unwrapping for acclimatization, remove poly film completely—don’t just slit it and leave it draped over the reel. Partial wrapping creates microclimates where one side equilibrates while the other remains sealed, leading to the cross-web moisture imbalance that causes curl. For sheet stock on pallets, the same principle applies: remove shrink wrap or stretch film entirely before starting the acclimatization clock.

Warehouse Relative Humidity Checks

Paper is hygroscopic—it continuously exchanges moisture with surrounding air until reaching equilibrium. Warehouse RH directly determines the final moisture content of stored paper. A warehouse running at 60% RH in summer and 35% RH in winter produces corresponding swings in paper moisture, even if incoming material always arrives within specification.

Install calibrated RH/temperature loggers in multiple warehouse zones—near loading docks, in the center of storage areas, and close to conditioning rooms or production entrances. Pay particular attention to door lanes, corners, and upper racks where microclimates form. Log trends rather than single snapshots. Review weekly patterns and flag sustained deviations from target range (typically 45–55% RH for most converting operations).

Without climate control, implement seasonal storage protocols. During high-humidity months, increase air circulation with fans, avoid stacking pallets against exterior walls, and rotate stock more frequently to prevent long-term moisture absorption. During low-humidity months, shorten acclimatization time, use humidifiers in critical zones, and prioritize older stock that has already equilibrated over recently arrived material still losing moisture. Keep relative humidity stable to avoid cyclic wetting or drying that alters equilibrium moisture in the sheet, following TAPPI T 402 guidance for standard atmospheres.

Measuring and Monitoring Moisture Reliably

Accurate, repeatable moisture measurement is the foundation of window-based acceptance. Without reliable data, verifying incoming material, diagnosing defects, or holding suppliers accountable for out-of-spec deliveries becomes impossible.

Sampling per ISO 186, Lab vs Inline Methods, and Frequency & Logging Basics

ISO 186 defines the standard procedure for sampling paper and board for testing. The key principle: take multiple samples from different locations across the lot to account for within-batch variation. A single measurement from one reel’s outer wrap doesn’t represent an entire shipment.

For reel stock, ISO 186 recommends sampling from at least three reels per lot. From each reel, take samples from the outer layers (first few wraps after removing packaging), mid-depth (approximately halfway through), and near the core. This three-point sampling captures any radial moisture gradient developed during winding or storage. For sheet stock on pallets, sample from top, middle, and bottom of the stack across at least three different pallets. Avoid taking all samples from easily accessible locations—this introduces bias and may miss localized issues.

Record each measurement with a location identifier such as ‘Reel 3, outer wrap’ or ‘Pallet 5, bottom layer.’ Calculate the average and note the range. If the range exceeds your window’s total span—finding values from 6.2% to 9.1% within a single lot—that variability itself signals a supplier process-control issue requiring investigation.

Lab testing per ISO 287 is the reference method. It involves weighing a sample, drying it in a controlled oven at 105°C ± 2°C until constant mass, then reweighing to calculate moisture loss. This method is highly accurate and serves as the standard for contract specifications, supplier certificates, and dispute resolution. The downside: lab testing requires several hours per batch and dedicated equipment plus trained personnel.

Inline meters provide instant readings and are practical for routine receiving checks. Modern handheld pin-type or non-contact capacitance meters measure moisture in seconds, allowing operators to screen every incoming reel or pallet. The trade-off: inline meters require regular calibration against lab reference samples and are sensitive to basis weight, coating, and surface conditions. Establish and maintain a correlation curve between inline readings and reference method results. Always verify inline meter accuracy quarterly at minimum by testing known-moisture samples prepared via ISO 287.

Best practice: use inline meters for go/no-go receiving decisions (quick screening to confirm material falls within your acceptance window) and reserve lab testing for borderline cases, supplier disputes, and periodic verification. Documenting both inline and lab results in receiving logs with dates, lot numbers, and operator names.

Measurement frequency depends on supplier reliability and risk tolerance. For established suppliers with consistent performance history: measure every incoming lot with inline meters and perform lab verification monthly or quarterly. For new suppliers or those with recent quality issues: measure every lot with inline meters and conduct lab tests on a statistically significant subset until establishing a reliable baseline. For spot-market purchases or single-shipment trials: perform both inline and lab testing on all material before accepting into inventory.

Maintain a moisture log recording date, lot number, supplier, grade, measured moisture (inline and/or lab), measurement location per ISO 186 sampling, ambient warehouse RH and temperature, and pass/fail decision. Log both absolute values and in-window status to keep decisions simple on the floor. Review this log monthly to identify trends—such as a supplier gradually drifting toward the upper window boundary—and address them before they trigger rejections or defects.

The Moisture Window One-Pager: Printable Reference for Operations

The one-page reference chart presented earlier in this article consolidates moisture window management into a format QA, receiving, and production teams can print, laminate, and post at relevant checkpoints. This chart is designed for immediate operational use without requiring reference back to full documentation.

How to Use the Range-Band Chart with QA and Production Teams

The range-band chart serves as a shared reference between receiving, QA, and production. When a receiving operator measures incoming moisture at 8.1%, they immediately see it falls within the acceptable window (illustrative example: 6.5 – 8.5%) and mark the lot as ‘pass’ without escalating to management or waiting for lab confirmation. This speeds throughput and reduces decision-making friction.

For production teams, the chart provides context when line performance changes. If curl or telescoping appears mid-run, operators check the moisture log for the current lot, verify it’s within the window, and then investigate other causes—nip pressure, temperature settings, RH fluctuations in the converting room—rather than automatically attributing issues to the paper.

QA teams use the chart to track supplier performance over time. Plotting incoming measurements on a simple control chart with window boundaries marked visualizes whether a supplier consistently centers around the target, drifts toward one boundary, or exhibits high variation. Suppliers who stay within a narrower band (for example, 7.2–8.0% when the window is 6.5–8.5%) earn higher reliability scores and may qualify for expedited approval or larger-volume contracts.

Troubleshooting: Drift Detection and Corrective Actions

Even with well-defined windows and disciplined storage practices, moisture-related issues occasionally arise. The key is detecting drift early—before it escalates into rejected lots or line stoppages—and implementing corrective actions systematically. Supplier sales engineers should understand these troubleshooting steps to support customer conversations proactively.

What to Check First When Issues Appear

Run through this diagnostic sequence.

First, verify meter calibration by testing your inline moisture meter against a known-moisture reference sample. If the meter reads 8.9% on material that lab-tested at 7.8%, recalibrate before taking further action.

Second, review warehouse conditions by checking RH and temperature logs for the period material was stored. A sudden spike in RH can drive moisture into unwrapped stock within 24–48 hours.

Third, confirm acclimatization compliance by asking the receiving team if material completed the full acclimatization period. Rushed handling frequently causes issues that appear to be supplier problems but are actually internal process failures.

Fourth, cross-check supplier certificates by requesting the mill’s lab certificate for the specific lot and comparing the mill’s reported moisture (tested per ISO 287 at shipment) with your incoming measurement. A discrepancy exceeding 0.5 – 1.0 percentage points suggests moisture gain or loss during transit.

Look for widening spreads between minimum and maximum readings within a lot, or growing gaps between inline and lab values. If all internal factors check out and the supplier’s certificate shows compliant moisture but your incoming tests consistently read high or low, the issue likely lies in packaging, shipping-lane humidity exposure, or the supplier’s measurement method. This is the point to escalate to a supplier discussion.

When to Reject or Hold Material

Establish clear thresholds in receiving procedures. Material testing outside your defined window by more than 0.5 percentage points should be rejected unless a lab test per ISO 287 confirms it’s actually within range and the inline meter was in error. For example, if your window is 6.5–8.5% and incoming measurements show 9.2%, reject the lot pending lab confirmation.

Material falling just outside the window (within 0.3–0.5 percentage points) can be placed on hold and conditioned back into range. Slight, explainable edge-cases may run after conditioning and recheck. For slightly high moisture (8.6–8.8% in an 8.5% maximum window), extend storage time in a controlled low-RH environment. For slightly low moisture (6.3–6.5% in a 6.5% minimum window), use humidification or longer acclimatization in a higher-RH zone.

In some cases—especially for non-critical applications or when alternative supply isn’t available—you might accept marginally out-of-window material with documented risk acknowledgment. Notify production of the moisture condition, adjust line settings if possible, and monitor closely for defects. Log this as a non-conformance and discuss long-term corrective action with the supplier. Keep decision rules visible with the range-band chart.

How to Talk to Suppliers Using Evidence and Method IDs

When moisture issues recur, approach suppliers with objective data rather than vague complaints. A message stating ‘Your paper is always too wet’ generates defensiveness and achieves little. Instead, structure communication around measurable facts.

Subject: Moisture Specification Discussion — Lot #12345 and Recent Deliveries

First, state your defined window: ‘Our acceptance window for this grade is 6.5–8.5%, target 7.5%, per ISO 287.’

Second, provide measured values: ‘Lot #12345 arrived on 2026. Our receiving team measured 8.9% using an inline meter with 3-point sampling per ISO 186. Lab test confirmed 8.7% per ISO 287.’

Third, reference the supplier’s certificate: ‘Your certificate for this lot reports 7.9%. The 0.8-percentage-point increase suggests moisture gain during transit or storage. Can you review your packaging and shipping-lane humidity data?’

Fourth, describe observed defects: ‘This lot exhibited telescoping on three reels. Attached photos show lateral misalignment. Production held the material pending your feedback.’

Fifth, request corrective action: ‘Please confirm future shipments will meet our 6.5–8.5% window at time of delivery. We’re willing to work with you on seasonal packaging adjustments or tighter process control if needed.’

Share method IDs and records—sampling per ISO 186, test method per ISO 287, conditioning atmosphere per TAPPI T 402 if used. This evidence-based approach demonstrates professionalism, gives suppliers clear feedback they can act on, and creates records for ongoing quality tracking. Most reputable suppliers respond constructively when issues are framed with specific test methods, lot numbers, and photos rather than subjective complaints.

Where to Go Next: Resources and Connections

Moisture window management is one component of a broader quality-assurance and supplier-management strategy for kraft paper procurement. Once acceptance windows and conditioning routines are established, consider expanding knowledge in related areas.

Laboratory testing protocols provide deeper understanding of how to interpret complete lab reports covering not just moisture but also basis weight, burst strength, tear resistance, and other properties. The PaperIndex Academy offers educational guides on kraft paper testing and moisture control.

Supplier pre-qualification develops structured PQQ (pre-qualification questionnaire) processes verifying a supplier’s process-control capabilities, calibration records, and quality-management systems before awarding contracts. Understanding a supplier’s moisture-control methods during pre-qualification reduces downstream issues.

Contract specifications translate moisture windows into enforceable contract language, including acceptance criteria, sampling methods (ISO 186), test methods (ISO 287), remedies for non-conformance, and packaging requirements. Clear contract terms reduce disputes and clarify both parties’ responsibilities.

For buyers seeking verified kraft paper suppliers who demonstrate consistent process control, PaperIndex connects them with over 6,700 suppliers across 8,400+ product categories in 195 countries. Buyers can find kraft paper suppliers and submit RFQ & receive quotes free—all without transaction fees or commissions.

For supplier sales engineers and mill representatives looking to connect with global buyers and demonstrate quality-control capabilities, PaperIndex offers a lead-generation platform. Suppliers can join free & connect with kraft paper buyers, showcase certifications and test methods, and build long-term business relationships based on verifiable performance. Alternatively, existing members can connect with buyers to expand their customer base.

PaperIndex is a neutral, non-transactional marketplace. We connect buyers and suppliers but do not broker deals, handle payments, or charge commissions. All negotiations, pricing, and transactions occur directly between trading partners.

Moisture Window One-Pager: Print-Ready Reference Chart

Module: Definition

A moisture window is an acceptable range (not a single target) within which kraft paper maintains stable converting performance. Moisture window → affects → curl/telescoping risk. Storage/conditioning practices → affect → stability. Consistency within range beats chasing exact targets for runnability.

Module: Acceptance Window (min/target/max)

Illustrative example for general-purpose kraft grades:

Visual Range-Band Chart:

REJECT | CAUTION | ACCEPT | CAUTION | REJECT

<6.5% | 6.5%–6.8% | 6.8%–8.2% | 8.2%–8.5% | >8.5%

(min) (target 7.5%) (max)

Minimum (lower boundary): 6.5% — below this, paper becomes brittle and prone to cracking

- Target (nominal center): 7.5% — supplier’s specification midpoint from mill process control

- Maximum (upper boundary): 8.5% — above this, excessive moisture causes curl, telescoping, and dimensional instability

Note: These are illustrative figures. Actual windows vary by grade (virgin vs. recycled), basis weight, and application. Use supplier lab data from recent shipments (3–6 months) to set your specific boundaries.

Module: Sampling & Measurement Basics

- Follow ISO 186 (sampling) for representative results. Sample minimum 3 reels per lot; take 3 points per reel (outer wrap, mid-depth, near core).

- For sheet stock: sample from top, middle, and bottom of stack across multiple pallets.

- Use inline meters for receiving checks; establish and maintain a correlation curve against the reference method. Verify quarterly against ISO 287 (oven-drying reference method).

- Document: date, lot number, measurement locations, ambient RH/temperature, pass/fail decision.

Module: Storage/Conditioning Checklist

☐ Acclimatization time: 24 hours minimum (standard reels <1,000mm), 48 hours (jumbo reels or heavy basis weights)

☐ Remove all protective wrapping completely before starting acclimatization clock—partial wrapping creates moisture imbalance

☐ Stage shipments in transition area if large temperature differential exists (cold container → warm warehouse)

☐ Target warehouse 50% ± 2% RH; log weekly trends with calibrated RH/temperature monitors in multiple zones. Focus on door lanes, corners, and upper racks where microclimates form.

☐ Seasonal protocols: high-RH months = faster stock rotation; low-RH months = prioritize equilibrated stock, shorten acclimatization. Reference TAPPI T 402 for standard conditioning atmospheres.

Module: Troubleshooting Flags

- Curl increase after first slits → check cross-web moisture uniformity; verify full acclimatization time completed

- Telescoping or starring on unwind → measure incoming moisture immediately; reject if exceeds upper boundary; inspect warehouse RH conditions

- Moisture spread (max–min) growing across samples → contact supplier for mill process-control review

- Inline sensors drifting from lab correlation → recalibrate and verify reference method alignment

- Supplier trending toward window boundary over time → request recent lab certificates; consider seasonal window adjustment

- Defects appear mid-run despite in-window moisture → investigate nip pressure, temperature settings, converting-room RH before attributing to paper

Print this chart and post it at receiving docks, QA labs, and production-floor entry points. Update the acceptance window values (min/target/max) based on your specific grades and supplier performance data.

Summary: The Core Principle of Moisture Window Management

Managing kraft paper moisture through defined windows—rather than chasing absolute target numbers—delivers more reliable converting performance and reduces downstream waste. The three core assertions that govern this approach are: (1) acceptable windows → reduce → curl/telescoping risk, (2) storage/conditioning practices → materially affect → stability, and (3) consistency within range → beats → exact target precision for runnability.

By setting evidence-based min/target/max boundaries using supplier lab data, implementing structured sampling per ISO 186 and measurement per ISO 287, maintaining disciplined storage and conditioning practices, and troubleshooting issues with objective data, buyers and converters reduce line stoppages while supplier sales engineers strengthen customer relationships through clear, verifiable expectations.

The one-page reference chart provided in this article equips operational teams with actionable guidance they can apply immediately. Print it, post it at key checkpoints, and customize the acceptance window values to match specific grades and supplier capability. Over time, performance history reveals which suppliers consistently deliver within the window, which shipping lanes require packaging adjustments, and which seasonal factors demand proactive management.

Moisture management is foundational quality assurance. Systematic window-based approaches create a stable platform for optimizing all other aspects of kraft paper sourcing, supplier relationships, and converting operations.

Our Editorial Process

Our expert team uses AI tools to help organize and structure our initial drafts. Every piece is then extensively rewritten, fact-checked, and enriched with first-hand insights and experiences by expert humans on our Insights Team to ensure accuracy and clarity.

About the PaperIndex Insights Team

The PaperIndex Insights Team is our dedicated engine for synthesizing complex topics into clear, helpful guides. While our content is thoroughly reviewed for clarity and accuracy, it is for informational purposes and should not replace professional advice.