📌 Key Takeaways

Double-wrapping food isn’t a training problem—it’s a sign that staff don’t trust the paper to hold up.

- Trust the Paper, Use Less Paper: When wrapping paper performs the same way every time, staff stop grabbing backup sheets out of habit.

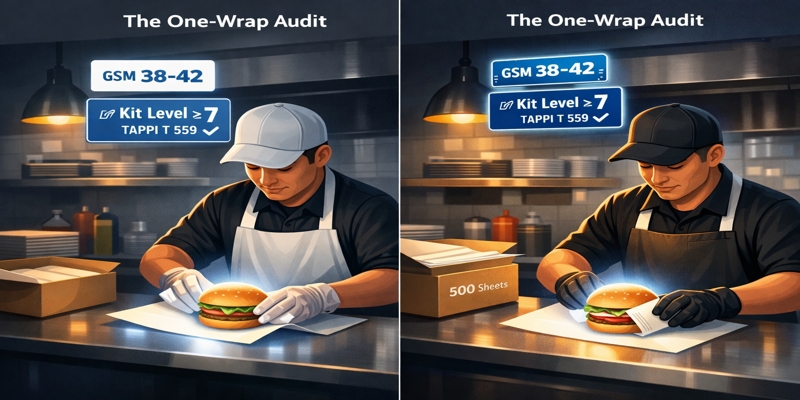

- Three Specifications Matter Most: Paper weight (GSM), grease resistance (kit level), and how well it matches your actual menu items determine real-world success.

- Test Before You Buy: A fifteen-minute trial with your greasiest item during a real rush reveals what lab specifications can’t predict.

- Vague Labels Hide Problems: Terms like “greaseproof” or “food safe” don’t tell you how long the paper blocks grease or at what temperature.

- One-Wrap Targets Double Carton Life: Cutting from two sheets to one means a 500-count box lasts three days instead of less than two.

Specifications-driven confidence beats insurance-wrapping every time.

Food service operators and procurement managers sourcing wrapping paper will find a clear spec framework and testing protocol here, preparing them for the detailed guidance that follows.

~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~

Grease spots bleeding through the wrapper before the customer even unwraps their food. A second sheet grabbed automatically at the make line. The wrap carton running empty mid-service—again.

Sound familiar?

If your kitchen burns through wrapping paper faster than expected, the team isn’t being wasteful. They’re protecting themselves. When paper feels flimsy or grease soaks through during a busy lunch rush, grabbing a second sheet becomes the only reliable insurance against complaints and remakes.

Here’s what most operators miss: double-wrapping is rarely a training problem. It’s a confidence problem created by unclear or mismatched specifications. When staff don’t trust the paper, they use more paper.

The fix starts with understanding three specifications—GSM, grease resistance, and fit-for-use—and verifying them with a quick in-kitchen trial before committing to a full order. Get those right, and one wrap can reliably do the job that two currently struggle to accomplish. That’s the practical goal: hitting a consistent one-wrap target across your highest-grease menu items.

Why Double-Wrapping Happens

Double-wrapping clusters around high-grease, high-heat menu items. Burgers straight off the grill, fried chicken sandwiches, loaded breakfast items, saucy burritos—these are exactly the items where failure shows immediately and embarrassingly.

The behavior is entirely rational. When wraps leak, customers complain. When paper tears mid-handoff, someone remakes the order. After experiencing a few of these incidents during a rush, an extra sheet becomes automatic. Self-defense, not carelessness.

The root cause typically traces back to vague supplier specifications. Labels like “greaseproof” or “food safe” don’t communicate how much grease the paper actually blocks, for how long, or at what temperature. Without clear numbers, operators can’t match paper performance to menu demands. When matching becomes impossible, layering becomes inevitable.

Specifications (specs) written as vibes—”greaseproof,” “premium,” “burger wrap”—invite interpretation. Two suppliers can ship papers that look similar but behave differently. The make line compensates with more paper.

This is the shift that matters: moving from “insurance wrapping” to spec-driven confidence.

What Double-Wrapping Creates on the Floor

The operational consequences compound quickly across three dimensions.

Accelerated stock-outs. When every burger requires two wraps instead of one, a 500-count carton serves 250 items rather than 500. Reorder cycles shorten dramatically, and mid-shift scrambles to find backup supplies become routine. The U.S. EPA’s Sustainable Materials Management (SMM) Hierarchy emphasizes that source reduction—reducing unnecessary consumption—is the most effective strategy for waste prevention.

Increased trash volume and mess. Double the paper means double the waste entering bins. Prep stations accumulate torn scraps and discarded sheets. Trash runs increase during service.

Inconsistent customer experience. Some staff double-wrap habitually while others don’t. Customers notice when their sandwich arrives wrapped differently than last week. Small inconsistencies erode the perception of operational control.

Training becomes harder. New staff copy the visible habit (“two sheets”) instead of learning when one sheet is actually sufficient.

The fix is not a pep talk. It’s a wrap that behaves the same way, case after case.

The Spec Trio That Reduces Double-Wrapping

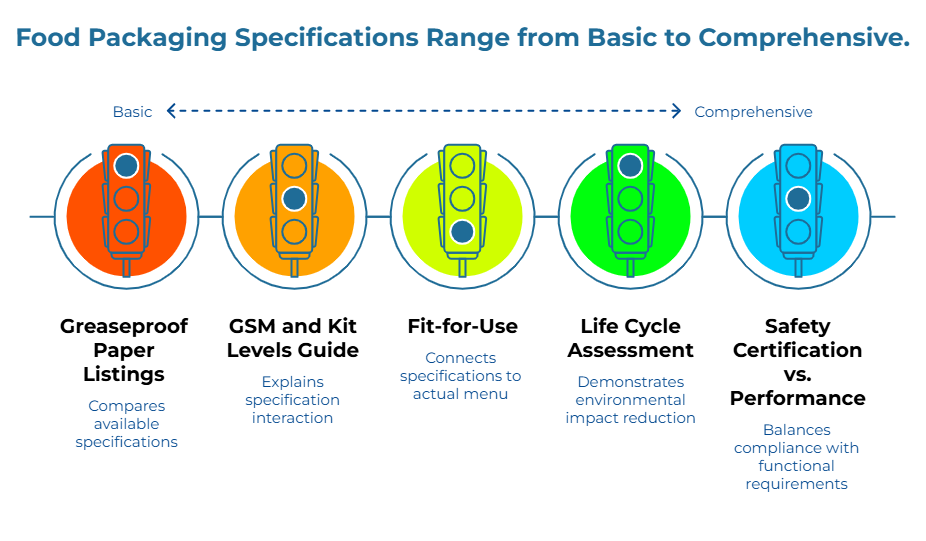

Three specifications matter most when selecting paper for greasy menu items. Understanding what each measures—and what it doesn’t—prevents both over-specification and costly mismatches.

GSM indicates paper weight, not grease resistance. A 45 GSM sheet feels more substantial than a 30 GSM sheet. But GSM alone doesn’t predict whether grease will soak through. A heavy paper without proper surface treatment can still fail within minutes of contact with a hot, oily item. Equal GSM still doesn’t guarantee equal performance; treatments and converting quality matter.

Grease resistance requires a specific measure. One widely used rating system is the kit level, tested according to the TAPPI T 559 method. Kit levels are measured on a standard 1–12 scale; a higher value indicates a paper’s ability to repel more aggressive solvents and oil. When requesting quotes, ask suppliers for the specific test method used and the actual result—not just a general ‘greaseproof’ claim. Buyers can review greaseproof paper listings to compare available specifications before initiating supplier conversations.

For operators seeking deeper understanding of how these specifications interact, the guide on GSM and kit levels in food packaging paper explains the relationship in practical terms.

Fit-for-use connects specifications to your actual menu. A kit level of 6 might work perfectly for a grilled cheese sandwich but fail completely for a double bacon cheeseburger. The food’s fat content, temperature at wrapping, and expected hold time before customer handoff determine what specification actually works. No single number works for every item.

Real food adds heat softening, condensation, and pressure at folds and seams. Fit-for-use is clarified by naming the application and validating it with a quick trial.

Life Cycle Assessment (LCA) studies in food packaging demonstrate that optimizing specification—rather than simply minimizing weight—reduces net environmental impact by preventing food waste and operational redundancy.

When evaluating suppliers, the framework for balancing safety certification with performance specifications helps weigh both compliance documentation and functional requirements together.

Measuring Your One-Wrap Target: A Practical Worksheet

Before requesting samples from suppliers, quantify current usage patterns. This comparison reveals how significantly double-wrapping affects inventory turnover.

Example calculation:

| Metric | Current (Two-Wrap) | Target (One-Wrap) |

| Wraps per item | 2 | 1 |

| Items per day | 150 | 150 |

| Wraps used daily | 300 | 150 |

| Days per 500-count carton | 1.7 | 3.3 |

At 150 items per day, double-wrapping consumes 300 sheets, exhausting a 500-count carton in 1.67 days. Transitioning to a single-wrap spec extends that same carton to 3.33 days—a 100% increase in inventory lifespan.

Blank worksheet for your menu:

Use this template to track double-wrapping across your highest-grease items:

| Item | Wraps per item (today) | Wraps per item (target) | Items per day | Wraps per day (today) | Wraps per day (target) |

| Hot burger | |||||

| Fried chicken sandwich | |||||

| Saucy burrito | |||||

| [Your item] |

The goal is understanding usage patterns clearly enough to specify paper that actually matches operational needs.

How to Write a Clearer Purchase Spec (and Verify It)

What to Request on Quotes and Purchase Orders

A clean spec can fit in three lines. This structure prevents interpretation gaps and makes quotes comparable:

- GSM range appropriate for the application (food wraps commonly fall between 30–50 GSM depending on intended use)

- Grease resistance: named test method plus reported result (for example, “Kit level 7 minimum per TAPPI T 559“)

- Intended use: hot, greasy handheld; expected hold time; heat lamp exposure (Yes/No); and storage humidity

Example wording:

“Food wrapping paper, GSM 38–42, grease resistance: kit level 7 minimum (tested to TAPPI T 559). Intended use: hot handheld items with visible grease, 4–6 minute hold time under heat lamps. Must resist strike-through and tearing during standard wrapping and carry.”

Also request sample availability for in-kitchen verification before committing to volume orders. Operators sourcing treated food wrapping papers can explore greaseproof paper suppliers to compare options across verified vendors.

Suppliers unable to provide specific test results may not be testing their products consistently—a useful signal during supplier evaluation. Buyers can submit an RFQ with these specifications to receive comparable quotes from verified suppliers.

What Documentation Supports Food-Contact Confidence

For food-contact materials, documentation requirements vary by market and specific application. In the United States, FDA 21 CFR 176.170 establishes requirements for paper and paperboard intended for food contact. Independent testing organizations such as ISEGA provide third-party verification for food contact materials in various markets.

Rather than accepting vague “food safe” claims, request documentation showing compliance with applicable standards for your specific use case. The guide on how to audit supplier safety documentation provides a structured approach to verifying these claims.

Quick In-Kitchen Trial Protocol

Before committing to a full order, verify performance under actual operating conditions:

- Pick the item that triggers double-wrapping most—typically your highest-grease menu item

- Wrap using a single sheet of sample paper

- Hold for your typical service time (commonly 4–7 minutes under heat lamps or in a warming drawer)

- Inspect for strike-through—is grease visible on the outside surface?

- Check structural integrity—did the paper tear at fold points during handling?

- Assess customer-hand feel—would this handoff feel professional?

- Repeat with at least two different operators and record outcomes

Conduct trials during peak service periods (e.g., 12:00 PM – 1:30 PM) to account for maximum heat lamp exposure and operator speed. Paper performing adequately under ideal conditions may fail under the heat, humidity, and rushed handling of a real lunch rush. Three to five samples across different service conditions provides a practical answer.

Frequently Asked Questions

What GSM range works for burger wraps?

Food wraps typically range from 30–50 GSM, with standard burger wraps often settling between 35–45 GSM, but GSM alone doesn’t determine success. Grease resistance appropriate for the burger’s fat content and your hold time matters equally. A 38 GSM paper with strong grease resistance often outperforms a 45 GSM paper with inadequate treatment. Start with the wrap your team currently trusts, confirm its GSM and grease rating, then set a range and grease-performance requirement for your specific use case.

What does kit level actually measure?

Kit level rates grease resistance on a 1–12 scale based on how well paper repels increasingly aggressive oil and solvent mixtures under standardized test conditions. Higher numbers indicate greater resistance. Standard burgers and sandwiches typically perform well with Kit levels between 5 and 7. Heavy-grease items like fried chicken or menu items with long hold times often require Kit 8–10. The rating is most useful when paired with the supplier’s named test method and reported result.

Why does paper sometimes leak despite a high kit rating?

Kit level testing occurs under controlled laboratory conditions. Real-world factors—extended hold times, heat lamp exposure, mechanical stress from folding and handling, humidity during storage—can exceed those conditions. A kit rating reflects a defined test, but real food adds heat, steam, condensation, and stress at folds and seams that can expose weak spots. Specification sheets describe potential performance; in-kitchen trials reveal actual performance in your environment.

How quickly can new wrapping paper be tested?

A meaningful test requires wrapping your greasiest item, holding it for your standard time, and inspecting both the inside and outside surfaces. The entire process takes under fifteen minutes per sample. Testing three to five samples during an actual service rush, with more than one operator involved, provides confidence before committing to volume purchases.

Key Terms to Know

The following four technical parameters define performance expectations:

Double-wrapping means using two sheets (or a sheet plus a bag) to prevent grease from soaking through and paper from tearing during handling.

GSM (grams per square meter) measures paper weight per square meter. It signals sheet “substance” but doesn’t guarantee performance on its own.

Kit level is a common grease-resistance rating for treated papers, typically ranging from 1 to 12. Higher numbers indicate greater resistance, though the specific test method matters.

Strike-through describes grease soaking through to the paper’s outside surface—the visible failure that triggers complaints.

Recommended Next Reading

For comprehensive guidance on specification selection, start with the complete guide to GSM and kit levels in food packaging paper.

The framework for balancing safety certification with performance specifications shows how to keep food-contact confidence and on-line reliability in the same specification conversation.

General waste-prevention guidance is available in the U.S. EPA’s tools for preventing and diverting wasted food.

The PaperIndex Academy offers additional frameworks for sourcing, specification, and supplier verification across food packaging applications. Operators ready to source can connect with food packaging paper suppliers directly through the marketplace. For context on PaperIndex’s marketplace philosophy, see why PaperIndex stays neutral.

Disclaimer:

This article provides general educational guidance about food packaging paper specifications. Requirements for food-contact materials vary by jurisdiction, application, and specific product characteristics. Verify that any packaging materials meet applicable regulations for your specific use case before purchase.

Our Editorial Process:

Our expert team uses AI tools to help organize and structure our initial drafts. Every piece is then extensively rewritten, fact-checked, and enriched with first-hand insights and experiences by expert humans on our Insights Team to ensure accuracy and clarity.

About the PaperIndex Insights Team:

The PaperIndex Insights Team is our dedicated engine for synthesizing complex topics into clear, helpful guides. While our content is thoroughly reviewed for clarity and accuracy, it is for informational purposes and should not replace professional advice.