📌 Key Takeaways:

Price comparisons without specification alignment create expensive chaos that multiplies with every additional quote.

Specification Parity Precedes Price Discussion: Meaningful cost comparison requires identical basis weight, moisture content, COBB values, and test method alignment before any pricing conversation begins.

Normalize Logistics Assumptions First: FOB versus delivered pricing, freight calculations, and Incoterm variations must be standardized to the same basis or price gaps become meaningless noise.

Document Everything in the RFQ Template: Explicit specification targets, tolerance ranges, test protocol references, and lane assumptions prevent costly rework and internal disagreement during evaluation.

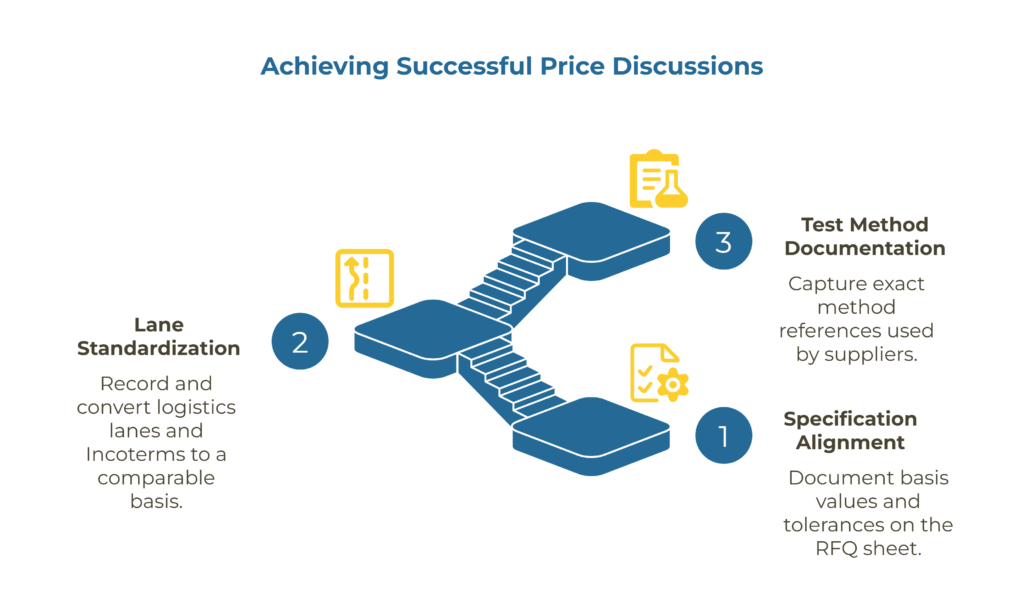

Use the Three-Step Foundation: Align specifications across suppliers, standardize logistics lanes and terms, then capture exact test method references before requesting any price information.

Convert Methodology Noise into Market Signals: When kraft paper suppliers quote different moisture targets or use different COBB test methods, apparent price differences reflect testing variations rather than true market positioning.

Specification truth transforms sourcing from reactive problem-solving into strategic advantage.

For kraft paper procurement teams and supply chain professionals managing complex sourcing decisions, these principles establish the governance foundation that makes “best price” discussions actually meaningful.

The Spec-True Mindset: Make Kraft Paper Quotes Comparable

More quotes don’t fix chaos. They amplify it when the quotes aren’t comparable.

The conference room tension is familiar. Your procurement team has three kraft paper quotes spread across the table, each claiming to meet your specifications. The prices vary by 15%, creating immediate pressure to choose the lowest number. Finance wants explanations. Operations questions whether the cheapest option will actually run on your lines.

You’re experiencing the most expensive misconception in kraft paper sourcing: that price comparison means anything without specification truth. When teams rush to “what’s your best price?” before agreeing on specs, test methods, and logistics lanes, they end up comparing noise rather than value.

The solution requires adopting what leading procurement teams call the “spec-true mindset”—a governance principle that makes specification comparability the prerequisite for any meaningful price discussion.

Why Price Comparisons Fail Without Spec Parity

Price lines look deceptively comparable in a spreadsheet. Beneath the surface, three critical misalignments systematically distort every comparison.

Hidden specification deltas drive real performance and cost differences yet often vary by supplier data sheets. Basis weight tolerances, moisture content, COBB water absorption values, and tensile strength measurements can differ significantly between quotes that appear similar on paper.

Lane differences create false price signals through freight, handling, and risk allocation variations. A quote showing FOB mill terms cannot be meaningfully compared to delivered-to-plant pricing without normalization of logistics assumptions.

Mismatched test methods produce apples-to-oranges values even when the numbers look close. ISO standards and TAPPI Test Methods often yield different results for identical materials, making direct comparison impossible without adjustment.

The fundamental truth: until specifications, lanes, and test methods are aligned, “lowest price” becomes a mirage that leads to costly mistakes downstream.

The Spec-True Principle in Practice

The spec-true approach operates on a simple but powerful rule: price comparisons require documented specification and lane normalization before any numbers discussion begins.

This governance principle demands that teams agree on specification parity—identical basis values and test protocols—plus comparable logistics assumptions before evaluating price. The principle applies whether sourcing virgin or recycled kraft, bleached or unbleached grades, or specialty liner applications.

Spec-true sourcing isn’t a demand for brand-identical products. Equivalence suffices, but “look-alike” materials without documented parity don’t qualify. The framework also isn’t a barrier to supplier diversity—it’s the guardrail that makes diverse supply bases genuinely comparable.

When suppliers quote to different moisture targets or use different COBB test methods, apparent price gaps often reflect test methodology noise rather than market reality. Normalize first, then evaluate price differences as meaningful market signals.

Normalization Rules: The Three-Step Foundation

Successful spec-true implementation requires systematic normalization across three dimensions before opening any price discussion.

Specification Alignment: Document basis values and tolerances on the RFQ sheet with explicit targets for GSM, moisture content, COBB water absorption, and tensile properties. Note any allowable deltas explicitly rather than assuming suppliers understand unstated tolerances.

Lane and Terms Standardization: Record the logistics lane and Incoterm quoted by each supplier, then convert everything to a comparable basis. Whether normalizing to delivered-to-plant or FOB plus standardized freight, consistency enables true comparison.

Test Method Documentation: Capture exact method references suppliers used to derive datasheet values. Values quoted under different testing standards must be adjusted or flagged before price evaluation begins.

This documented normalization reduces RFQ churn and internal disagreement by establishing shared assumptions that all stakeholders can audit and verify.

Spec-First RFQ Pre-Flight Checklist

Before requesting any price information, verify completion of these essential steps:

-

-

- Confirm identical target specifications across all suppliers, including basis values and test protocol references

-

- Record lane and Incoterm details for each quote; establish conversion methodology to comparable basis

-

- Capture specific test method references used to produce all datasheet values

-

- Flag any tolerance differences and moisture or COBB variations for detailed review

- Assign clear ownership for maintaining the normalization documentation

-

This checklist transforms RFQ governance from reactive problem-solving into proactive quality control.

Worked Example: From Chaos to Clarity

Consider a realistic scenario that demonstrates both the problem and the solution.

Initial Mismatch: A buyer collects three kraft paper quotes. Supplier A quotes FOB mill with 80 GSM, 7% moisture, COBB 30 using ISO methodology. Supplier B quotes delivered pricing with 80 GSM, 6% moisture, COBB 25 using TAPPI methods. Supplier C quotes FOB port with 78 GSM, 7% moisture, COBB 30 using ISO standards.

At first glance, Supplier B appears costliest per ton. However, this comparison rests on multiple uncontrolled variables.

Normalization Process: Convert all quotes to delivered-to-plant using identical freight assumptions. Align GSM specifications to the stated target, treating the 78 GSM quote as potentially out-of-specification unless tolerance allows ±2 GSM variation. Note that Supplier B’s COBB measurement uses a different methodology requiring adjustment for method-comparable values. Flag the moisture content delta since specification requires 7% and Supplier B must confirm compliance or re-quote.

Clarified Comparison: Once lanes and test methods align and the underweight quote is addressed, the previously “highest price” supplier may no longer be highest. The apparent cost gap was primarily lane and methodology noise rather than true market positioning.

The Business Impact of Specification Governance

Organizations implementing spec-true sourcing experience measurable improvements across multiple dimensions. Project timelines become predictable because materials perform as expected during trials and production runs. Budget accuracy improves because quotes reflect genuine comparability rather than hidden specification variations.

Negotiations become more effective because discussions focus on legitimate value differences—service levels, payment terms, technical support—rather than confusion about basic product comparability. Quality outcomes improve because specification requirements are established and verified before material selection occurs.

The cultural shift proves equally valuable. Procurement teams develop stronger supplier relationships based on clear communication, while internal stakeholders gain confidence in sourcing decisions because the selection logic becomes transparent and defensible.

Moving From Price-First to Spec-First Thinking

The transition requires acknowledging that conventional approaches create more problems than they solve. Most kraft paper sourcing challenges trace back to specification assumptions that seemed reasonable during quoting but proved problematic during implementation.

Organizations serious about improving sourcing outcomes must establish specification governance as non-negotiable. This means refusing price discussions until specification requirements are documented and logistics assumptions are normalized across all potential suppliers.

The discipline pays dividends beyond individual projects. Teams consistently applying spec-true principles develop institutional knowledge about which specifications actually matter for their applications, creating a foundation for increasingly effective sourcing decisions over time.

Frequently Asked Questions

When are small specification deltas acceptable for price comparison?

Small deltas aren’t acceptable until they’re recorded, analyzed, and normalized. Deltas can be accepted after the team documents their impact on performance and adjusts the comparison methodology accordingly.

Who should own the normalization process?

Ownership must be explicit in the RFQ template, creating shared documentation that finance, operations, and sourcing teams can all access and audit for changes.

From Governance to Results

Spec-true RFQ governance transforms “what’s your best price?” from a premature question into an informed inquiry. Establish equivalence first, align lanes and test methods, then document everything in the RFQ template.

Only then does “lowest price” or “best value” carry actual meaning. Specifications serve as the blueprint for successful sourcing decisions. When specifications remain unclear, everything built on that foundation becomes unstable.

The spec-true mindset provides the clarity necessary to transform kraft paper sourcing from reactive problem-solving into strategic advantage. Normalize specifications and lanes first, then invite quotes. When responses arrive, you’ll be comparing truth rather than noise.

Our Editorial Process

Our expert team uses AI tools to help organize and structure our initial drafts. Every piece is then extensively rewritten, fact-checked, and enriched with first-hand insights and experiences by expert humans on our Insights Team to ensure accuracy and clarity.

About the PaperIndex Insights Team

The PaperIndex Insights Team is our dedicated engine for synthesizing complex sourcing topics into clear, helpful guides. While our content is thoroughly reviewed for clarity and accuracy, it is for informational purposes and should not replace professional advice.