📌 Key Takeaways

Wax paper fails on hot food because heat melts the coating—use greaseproof paper with documented specs for burgers, fries, and hot sandwiches.

- Wax Melts, Fiber Holds: Wax coatings soften and stick to hot food, while greaseproof paper resists grease through its fiber structure.

- Match Wrap to Menu: Cold items work with wax paper, but hot and greasy foods need greaseproof paper rated for the heat and fat level.

- Ask for Proof, Not Promises: Request Kit level ratings and food-contact documents before buying—suppliers who can’t provide evidence may not deliver quality.

- Screen Before You Commit: Wrap a hot, greasy test item, hold it for your normal service time, then check for sticking, transfer, or grease bleed-through.

- Labels Lie Without Context: “Food safe” and “nonstick” don’t mean a wrap handles high heat—verify the specific use conditions it was designed for.

The right wrap protects your product; the wrong one becomes the problem.

Food service operators and procurement managers sourcing food packaging for hot menu items will find practical selection and verification methods here, preparing them for the detailed comparison that follows.

~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~

The wrapper is melting.

Steam rises from a fresh-off-the-grill sandwich. The wax coating softens, turns glossy, then transfers onto the bun. A customer complaint is 30 seconds away.

This wrap worked fine for cold subs—what happened?

That failure isn’t random. It’s predictable, and it happens when operators treat all food wraps as interchangeable.

Wax paper is paper coated with a thin wax layer designed to resist moisture at cool temperatures. When exposed to high heat, that coating softens and can transfer onto food, compromising texture and safety.

Greaseproof paper achieves its barrier through fiber treatment—not surface coatings—making it thermally stable and capable of maintaining barrier integrity at temperatures reaching 220°C (428°F), far exceeding the failure point of wax coatings. For hot, greasy menu items, the practical difference determines whether the wrap protects your product or becomes the problem. Verification through documented specs, such as grease resistance ratings measured by Kit level testing, separates guesswork from confidence—an approach explored in depth in our guide to GSM and Kit levels in food packaging paper.

The “Melting Wrapper” Incident: What Failed (and Why It’s Predictable)

Picture lunch rush. Bacon cheeseburgers coming off the flat-top, wrapped fast, stacked in the warmer. Within minutes, the wax paper looks wet. Translucent spots appear near the seams. Pull one out—the wrapper sticks to the bun. Peel it away and waxy residue stays behind.

The product is ruined. The customer is unhappy. And now there’s a question: is this a food safety issue that needs documentation?

This degradation is mechanical. Wax paper was designed for cold applications: deli wraps, sandwich storage in the cooler, layering between stacked cookies. The wax creates a moisture barrier and non-stick surface at room temperature. Introduce sustained heat, and the barrier becomes the contaminant.

The confusion happens because the packaging looks similar. Both wax paper and greaseproof paper come on rolls, feel smooth, and appear to do the same job. But the label “wax paper” hides the real requirement: heat behavior, grease resistance, and food-contact suitability for the actual conditions of use.

What Wax Paper Actually Does (and Where It Breaks Down Under Heat)

Think of wax on hot food the way you’d think of a candle near a stovetop. Heat changes the material. The coating that functions as a barrier becomes soft, mobile, and prone to transfer.

Wax paper works by applying a thin paraffin or soy-based wax layer to the paper surface. This coating blocks moisture migration at cool temperatures, provides release properties for sticky foods, and creates a smooth wrapping surface. None of these properties survive sustained high heat.

Why it looks fine cold but fails hot: at room temperature, the wax stays solid and stable. As surface temperature climbs, the wax softens progressively. Glossiness appears first, then tackiness, then visible transfer to the food. Typical failure signs include translucent patches, residue transfer, and limp folds—often concentrated at creases and seams where heat and grease accumulate. The failure isn’t about hitting a single “melting point”—different wax formulations behave differently. What matters is the principle: wax coatings are not engineered for hot-holding or direct contact with freshly cooked food.

Wax Paper vs Greaseproof Paper for Hot Food: The Practical Difference

The core distinction comes down to how the barrier is created.

Wax paper relies on a surface coating. The paper itself is standard; the wax layer does the work. Remove or compromise that layer, and the barrier disappears.

Greaseproof paper achieves resistance through the fiber structure itself. While many greaseproof papers use extensive fiber refining (hydration) to create a dense, non-porous sheet, modern high-performance variants often utilize aqueous-based, PFAS-free sizing agents to achieve Kit levels of 7 or higher without the use of fluorochemicals or surface wax.

For hot, greasy items like burgers, fried sandwiches, or bakery goods fresh from the oven, properly specified greaseproof paper maintains its integrity. The barrier stays in the paper, not on your food.

This matters for four reasons:

- Texture: Wax transfer creates unpleasant mouthfeel and appearance

- Compliance: Coating transfer violates the ‘Conditions of Use’ for which standard wax papers are validated (typically Room Temperature or below per FDA guidelines)

- Handling: Degraded wraps tear, stick, and slow down service

- Perceived cleanliness: Customers notice when packaging fails visibly

The Real Spec Behind “Greaseproof”: Grease Resistance and the Kit-Level Idea

Not all paper labeled “greaseproof” performs equally. The term itself isn’t regulated to a single standard, which means actual performance specs matter more than marketing language.

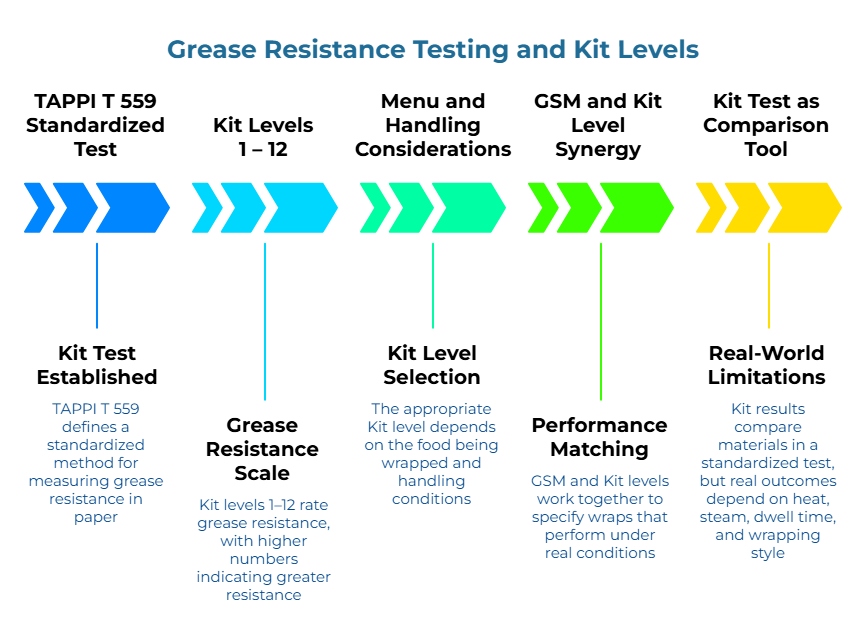

One common measure is the “Kit test,” standardized as TAPPI T 559. This test applies increasingly aggressive solutions to the paper surface and rates resistance on a scale — Kit levels 1–12 rate grease resistance, with higher numbers indicating greater resistance to grease penetration.

The Kit level that works depends on what’s being wrapped. A lightly greasy pastry needs different performance than a bacon cheeseburger dripping with rendered fat. There’s no single “right” Kit number—the goal is matching the spec to the menu and handling conditions.

When evaluating wraps, the question shifts from ‘Is this greaseproof?’ to ‘What’s the grease resistance rating, and does it match the use case?’ Understanding how GSM and Kit levels work together helps specify wraps that actually perform under real conditions.

Kit results compare materials in a standardized test context, but real outcomes still depend on heat, steam, dwell time, and wrapping style. Use Kit levels as a comparison tool, not a guarantee.

A Simple Selection Method: Match Wrap to Heat + Grease + Hold Time

Treat wraps like performance materials: specify the use-case, demand the right evidence, and run a quick in-house check before rollout.

Before sourcing any food wrap, answer these triage questions:

Temperature exposure: Will the wrap contact cold items, warm items, or food straight off the cooking surface?

Grease load: Is the item dry, lightly oily, or high-fat with rendered grease?

Hold time: Quick hand-off in seconds, or extended holding in a warmer for minutes?

Steam and moisture: Will the wrapped item generate steam that could affect barrier performance?

Direct contact: Does the wrap touch the food surface directly, or is there a liner?

| Use Case | Recommended Direction |

| Cold deli sandwiches, cheese wrapping | Standard wax paper acceptable |

| Warm, low-grease items (short hold) | Verify wrap tolerates mild heat |

| Hot sandwiches, fresh burgers | Greaseproof paper with documented heat stability |

| High-grease items (bacon, fried foods) | Higher Kit-level greaseproof, verified for grease load |

| Hot/steamy items with extended hold | Confirm wrap maintains integrity under sustained heat and moisture |

How to Verify Before a Full Rollout: Screening Checks + Supplier Evidence Stack

Don’t switch to a new wrap based on the label alone. Build a verification routine that catches mismatches before they reach customers.

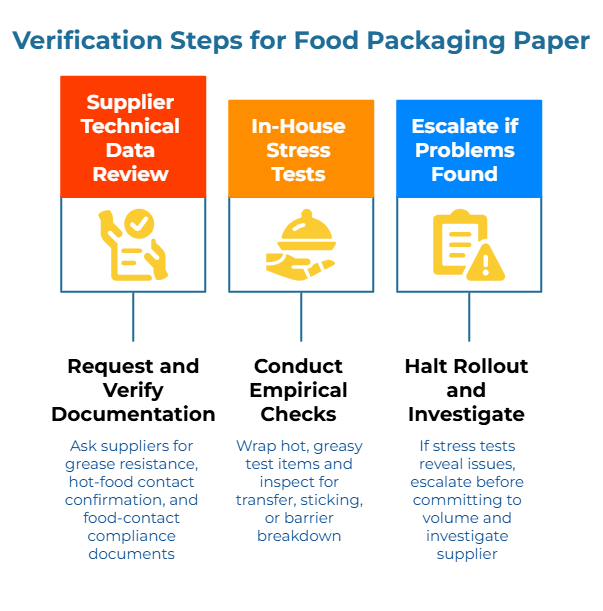

1. Verify the Supplier’s Technical Data Stack

Ask suppliers for:

- Grease resistance rating (Kit level or equivalent)

- Confirmation the product is designed for hot-food contact

- Food-contact compliance documentation for the relevant market

For US operations, FDA 21 CFR 176.170 addresses paper contacting aqueous and fatty foods, while 21 CFR 176.180 covers paper contacting dry food. EU operators can reference Regulation EC 1935/2004 as the framework regulation, with additional guidance available through resources like the German BfR Recommendation XXXVI for paper and board.

This evidence stack tells you whether the supplier can document performance—not just claim it. Learning how to audit food packaging paper suppliers for FDA and ISEGA safety systematically strengthens qualification processes.

2. Conduct Empirical ‘Stress Tests’ In-House

These are not certification tests. They’re quick in-house checks to catch obvious problems—similar to the 5-minute grease spot test that screens food packaging paper at receiving:

- Wrap a hot, greasy test item at peak service temperature

- Hold it for the typical service window (5, 10, 15 minutes)

- Unwrap and inspect: visible transfer? Sticking? Barrier breakdown?

- Repeat with a few samples across different menu items

If problems appear, escalate before committing to volume. Understanding how to verify food contact compliance beyond certificates helps separate reliable suppliers from those who cannot support quality requirements.

The High-Heat Wrap Selection & Verification Card

Use-Case Triage Questions

- Verify the peak thermal threshold of the contact surface

- Hold time before service?

- Grease/fat content of items being wrapped?

- Steam or moisture generation expected?

- Direct food contact, or with a liner?

Supplier Questions

- Documented grease resistance (Kit level)?

- Designed for hot-food contact?

- Food-contact compliance documentation for this market?

- Recommended use conditions and limitations?

Receiving Screening Routine (not certification)

- Inspect sample rolls for consistency

- Run hot-item hold test before approving volume

- Document results with photos

Red Flags to Reject

- Waxy smell or smoke on hot-food contact

- Visible wax transfer or glossy residue on food

- Wrapper sticking or tearing on removal

- Grease strike-through before expected hold time

- Supplier unable to provide performance documentation

Heat Tolerance Comparison: Wax Paper vs Greaseproof Paper

| Factor | Wax Paper | Greaseproof Paper (Spec’d for Heat) |

| Heat exposure behavior | Coating softens and transfers under sustained heat | Fiber-based barrier remains stable |

| Grease strike-through risk | Barrier compromised when wax degrades | Resistance maintained per documented Kit level |

| Handling outcomes | Sticking, tearing, service delays | Clean release, consistent performance |

| Typical failure signs | Glossy residue, waxy smell, visible transfer | Grease penetration only if mismatched to use case |

| Evidence/spec to request | Limited—designed for cold use | Kit level rating, heat tolerance confirmation, compliance docs |

For a systematic approach to balancing safety certification with performance specifications, the food packaging paper sourcing matrix provides a framework for evaluating these trade-offs.

Common Operator Myths That Cause Repeat Failures (and the Fix)

Myth: “All kitchen paper is basically the same.” Different papers are engineered for different jobs. Wax paper, greaseproof paper, parchment, and butcher paper utilize distinct chemistries and physical structures. Matching material to use cases prevents failures.

Myth: “If it says ‘food safe,’ it works for everything.” Food-contact approval means the material is safe for some applications—not all conditions, which is why ‘food safe’ is often a meaningless label without named standards and lot-linked documentation. Heat, grease, and hold time determine whether a specific wrap is appropriate..

Myth: “Nonstick means greaseproof.” Coatings can feel nonstick yet fail under heat. A wrap that releases cleanly at room temperature may still soften, transfer, or allow strike-through when hot grease is involved. Ask for grease resistance evidence, not just release properties.

Myth: “We’ve always used this wrap without problems.” Past performance with cold items doesn’t predict hot-item performance. Menu changes require wrap spec reviews.

Myth: “Our own test is good enough for compliance.” In-house screening catches obvious failures but doesn’t replace supplier documentation. Both are necessary: evidence from the supplier and verification in the operation.

Optimizing Your Wrap Standard is Critical for High-Volume Hot-Food Operations

Wrap failures create rework, complaints, and compliance questions that surface at the worst times. For operations where hot sandwiches, burgers, or fried items are central, wrap selection belongs in the spec sheet—not left to chance.

Start by auditing current wraps against the checklist above. Identify any contact with hot food without documented heat stability or grease resistance. For high-heat applications, consider upgrading to dry-wax styles or chemically grease-resistant greaseproof papers designed for these conditions—materials where the barrier is engineered into the product rather than applied as a heat-sensitive coating.

Then work with suppliers who can provide the evidence stack. For sourcing verified food packaging paper suppliers or requesting quotes with specific performance requirements, PaperIndex connects buyers directly with manufacturers who document their products’ capabilities. The PaperIndex Academy provides additional resources for navigating packaging specifications and supplier qualification.

Reducing rework and service failures starts with matching the wrap to the job.

Key Terms

- Wax paper: A substrate utilizing a paraffin or soy-based surface barrier; designed for cold or room-temperature applications

- Greaseproof paper: Paper achieving grease resistance through fiber refinement rather than surface coatings; suitable for hot-food contact when specified appropriately

- Kit level: A standardized measure of grease resistance (TAPPI T 559); higher numbers indicate greater resistance to grease penetration

- Strike-through: When grease penetrates and shows through the paper surface—a visible sign of barrier failure

- Food-contact compliance: Regulatory requirements governing materials that touch food; varies by market (US, EU, etc.)

Frequently Asked Questions

Can wax paper wrap hot sandwiches?

Wax paper is not recommended for hot sandwiches. The wax coating can soften and transfer to food when exposed to heat, affecting texture and raising food-contact concerns. For warm, lower-grease items with very short holds, wax paper may work—but for hot, greasy sandwiches, greaseproof paper designed for hot-food applications is the appropriate alternative.

Why does wax paper melt on hot food?

Wax paper has a paraffin or plant-based wax coating that softens when heated. This coating was designed for cold or room-temperature use. Heat causes the wax to become mobile and transfer onto food surfaces.

Wax paper vs greaseproof paper: which is better for burgers and fries?

Greaseproof paper is better for hot, greasy items. Unlike wax paper, greaseproof paper achieves its barrier through fiber treatment rather than a surface coating, remaining stable under heat and resisting grease penetration when properly specified.

What does Kit Level mean for grease resistance?

Kit level refers to a standardized test (TAPPI T 559) measuring paper’s resistance to grease penetration. Higher Kit levels indicate greater resistance. Matching the Kit level to the menu’s grease load ensures the wrap performs under actual use conditions—though real-world results also depend on heat, steam, and hold time.

What should I ask a supplier to prove wrap performance and safety?

Request the grease resistance rating (Kit level), confirmation the product is designed for hot-food contact, and food-contact compliance documentation relevant to the market. Suppliers unable to provide this documentation may not support quality requirements adequately.

Disclaimer:

This article provides educational guidance on food wrap selection and is not legal or regulatory advice. Verify compliance requirements with local regulatory authorities and qualified professionals for your specific market.

Our Editorial Process:

Our expert team uses AI tools to help organize and structure our initial drafts. Every piece is then extensively rewritten, fact-checked, and enriched with first-hand insights and experiences by expert humans on our Insights Team to ensure accuracy and clarity.

About the PaperIndex Insights Team:

The PaperIndex Insights Team is our dedicated engine for synthesizing complex topics into clear, helpful guides. While our content is thoroughly reviewed for clarity and accuracy, it is for informational purposes and should not replace professional advice.