📌 Key Takeaways

GSM measures paper weight, not bag strength—burst testing reveals rupture resistance under real-world pressure.

- Specify Both Metrics Always: GSM alone hides strength differences; require bursting strength in kPa with ISO 2758 or TAPPI T403 test methods.

- Name the Test Standard: ISO and TAPPI results differ—specify one method explicitly to prevent incomparable quotes and receiving disputes.

- Conditioning Prevents Drift: Paper properties shift with humidity; require ISO 187 conditioning statements so all suppliers test under identical atmospheres.

- Tolerances Make Specs Enforceable: “80 GSM” is a target, “80 GSM ± 3%” is a specification—without tolerances, QC becomes subjective debate.

- Map Failure Modes First: Define whether bags rupture, tear at handles, or wet-weaken, then specify the properties that prevent those exact failures.

Measurable specs eliminate supplier ambiguity and protect margins.

Procurement and operations teams sourcing paper bags for e-commerce, food delivery, or retail packaging will gain immediately enforceable RFQ language here, preparing them for the spec templates and supplier evaluation frameworks that follow.

Fast Answer

GSM (g/m²) tells how much paper weighs per square meter, not how well a bag will survive real-world stress. Burst-related metrics (bursting strength in kPa, plus normalized metrics like burst index) describe how much pressure the sheet withstands before rupturing, but only if the test method and conditioning atmosphere are stated.

Minimum viable spec set for paper bag material grades:

- GSM target + tolerance (g/m²)

- Burst requirement (state metric + unit and test standard, e.g., ISO or TAPPI)

- Conditioning/testing requirement (state the conditioning standard or controlled lab atmosphere)

- Sampling + acceptance language (simple, measurable, and aligned to QC)

A paper bag tears at checkout. The customer watches their order spill across the counter, and your brand takes the hit. That moment of failure rarely traces back to a single supplier mistake. It traces back to a specification that was never precise enough to prevent it.

You have likely seen it before: two suppliers quote the same GSM, yet one bag holds firm while the other ruptures under half the expected load. The difference is not luck. It is the gap between a number on a quote and a measurable, testable specification that predicts real-world performance.

By the end of this guide, you will know exactly what GSM and burst metrics mean, why one without the other tells an incomplete story, and how to write RFQ language that closes the door on ambiguous claims. No more comparing adjectives like “strong kraft” or “premium quality.” You will compare numbers, methods, and conditions that actually predict whether your bags will survive the journey to your customer’s hands.

What “Material Grade” Actually Means for a Paper Bag

When suppliers mention “grade,” they are not describing a quality ranking like a school report card. Grade refers to a bundle of measurable physical properties: basis weight, burst resistance, tensile strength, moisture content, and fiber composition, among others. Marketing terms like “heavy duty” or “premium” carry no standardized meaning. Two suppliers using identical language may deliver materials with vastly different performance characteristics.

This matters operationally because bag failures manifest in predictable ways. A bag that tears at the handle differs from one that ruptures at the base, and each failure mode connects to specific material properties. Tear resistance relates to tensile strength and fiber length. Rupture resistance connects to burst strength and sheet formation. Understanding grade as a collection of testable properties allows you to specify against the failure modes that matter most for your application.

The practical consequence is straightforward: if your specification says only “kraft paper bags, 80 GSM,” you have described weight but not strength. You have described fiber type but not formation quality. You have left the supplier to interpret what “good enough” means, and their interpretation may not match your customer’s expectations when that bag is in their hands.

GSM Explained: What Basis Weight Can and Cannot Tell You

GSM in One Line

GSM stands for grams per square meter (g/m²). It measures how much a one-square-meter sheet of paper weighs. Higher GSM means more material per unit area. That is all it guarantees.

The measurement is foundational because it affects cost, printability, and perceived quality. Heavier paper generally feels more substantial. It typically accepts ink better. It costs more per bag. But GSM alone does not tell you whether the bag will hold a three-kilogram order of takeout containers without tearing.

How GSM Is Tested

The standard method for determining grammage is defined in ISO 536[1]. The test is simple: cut a precisely measured sample, condition it under controlled humidity and temperature, weigh it, and calculate grams per square meter. The conditioning step matters because paper absorbs and releases moisture depending on ambient conditions. A sheet tested at 80% relative humidity will weigh more than the same sheet tested at 30% humidity.

This is why specifications must include conditioning requirements. Without them, a supplier in a humid climate and a buyer in an arid region may get different numbers from the same material. The paper has not changed. The measurement conditions have.

Where GSM Misleads Buyers

Consider two 80 GSM kraft papers. One uses long-fiber virgin pulp with strong inter-fiber bonding. The other uses recycled fiber with shorter fibers and weaker bonds. Both weigh exactly 80 grams per square meter. At 80 GSM, a typical virgin semi-extensible sack kraft can exceed 350 kPa (Burst Index > 4.4), whereas standard recycled test liner grades often range between 175–200 kPa (Burst Index 2.2–2.5) depending on the quality of the waste stream

Same GSM. Dramatically different performance.

This is the core limitation of weight-only specifications. GSM tells you about material quantity, not material quality. A well-formed sheet with strong fiber bonding at 70 GSM can outperform a poorly formed sheet at 90 GSM. Understanding gsm and burst factor: a specifier’s guide to paper bag strength explores this relationship in greater depth, but the principle is simple: you need both weight and strength metrics to predict performance.

Bursting Strength vs. Burst Index vs. “Burst Factor”

This is where terminology causes the most confusion in supplier communications. Three related terms appear on spec sheets, and they measure different things.

Bursting Strength (kPa): What the Tester Measures

Bursting strength is the pressure required to rupture a paper sample when hydraulic or pneumatic force is applied through a rubber diaphragm. The result is reported in kilopascals (kPa). The standard test method is defined in ISO 2758[2].

In North American contexts, the active standard is TAPPI T403. Buyers may still see references to ASTM D774, but this standard was withdrawn in 2010. For strict compliance, specify ISO 2758 or TAPPI T403.

The test simulates the kind of stress a bag experiences when contents press against the paper from inside. A bag carrying heavy items experiences internal pressure at the base and sides. Bursting strength tells you how much pressure the material can withstand before it fails.

Typical bursting strength values for packaging papers range widely. Lightweight tissue papers might test below 100 kPa. Heavy sack kraft designed for cement bags can exceed 500 kPa. For retail and food delivery paper bags, values between 200 and 350 kPa are common, though the right specification depends entirely on your application.

Burst Index (kPa·m²/g): Strength Normalized by Weight

Burst index takes the bursting strength result and divides it by GSM. The formula is:

Burst Index = Bursting Strength (kPa) ÷ Basis Weight (g/m²)

The result is expressed in kPa·m²/g. This normalized value allows comparison between papers of different weights. A lighter paper with high burst index may be more efficient than a heavier paper with low burst index, delivering equivalent performance with less material.

According to Smithers, this normalization is essential when evaluating paper efficiency because it reveals how effectively the fibers have been bonded and formed, independent of how much fiber is present[3].

“Burst Factor”: Define It, Then Confirm What Your Supplier Means

Here is where specifications fail most often. “Burst factor” is used inconsistently across markets and suppliers. While frequently confused with Burst Index (kPa . m2/g), the traditional technical definition for Burst Factor is Burst Strength in g/cm2 divided by Basis Weight in g/m2. Because this mixes units and is not part of modern ISO standards, you must explicitly ask the supplier for their calculation method.

When a supplier quotes “burst factor 22,” ask three clarifying questions:

- What formula did you use to calculate this number?

- What units is the result expressed in?

- What test standard did you follow?

Without these answers, you cannot compare the number to another supplier’s quote. You cannot verify incoming shipments against spec. You have a number without meaning.

The safest approach is to specify bursting strength in kPa with the test method explicitly named. This removes ambiguity entirely.

Why the Test Standard Matters

ISO 2758 and TAPPI T403 both measure bursting strength, but procedural differences can produce different results from the same sample. While both methods use the Mullen principle, ISO 2758 and TAPPI T403 differ in diaphragm specifications and clamping pressures; empirically, TAPPI results can sometimes read slightly higher (2–5%) than ISO results for the same paper, though this correlation varies by paper grade.

Specify the standard. State it in your RFQ. Require suppliers to confirm which method their test reports follow. This is not pedantry. This is how you ensure that the number on the certificate matches the number on your purchase order.

Why Higher GSM Does Not Always Mean Higher Strength

The relationship between weight and strength is not linear, and assuming otherwise leads to over-specification and unnecessary cost, or under-specification and bag failures.

Several factors determine strength independent of weight:

Fiber source and length. Virgin kraft pulp from softwood species like pine and spruce contains long fibers that interlock effectively. Recycled fiber has been shortened through repeated processing. Hardwood fibers are naturally shorter than softwood. Longer fibers generally produce stronger paper at equivalent weights.

Refining and bonding. The pulping and refining process affects how fibers bond to each other. Well-refined pulp with fibrillated fiber surfaces creates more contact points and stronger sheets. The same fiber, processed differently, yields different strength.

Sheet formation. How evenly the fibers distribute across the sheet during forming affects both strength and consistency. Poorly formed sheets have thin spots that become failure points.

Additives and sizing. Wet-strength agents, starch, and sizing chemicals modify paper properties. A sized paper with wet-strength treatment may hold up in humid conditions where an untreated paper at the same GSM fails.

The practical implication: when evaluating kraft paper grades for paper bags, ask suppliers about fiber source and any strength-enhancing treatments. Request both GSM and burst test results. Do not assume that paying for heavier paper automatically delivers proportionally stronger bags.

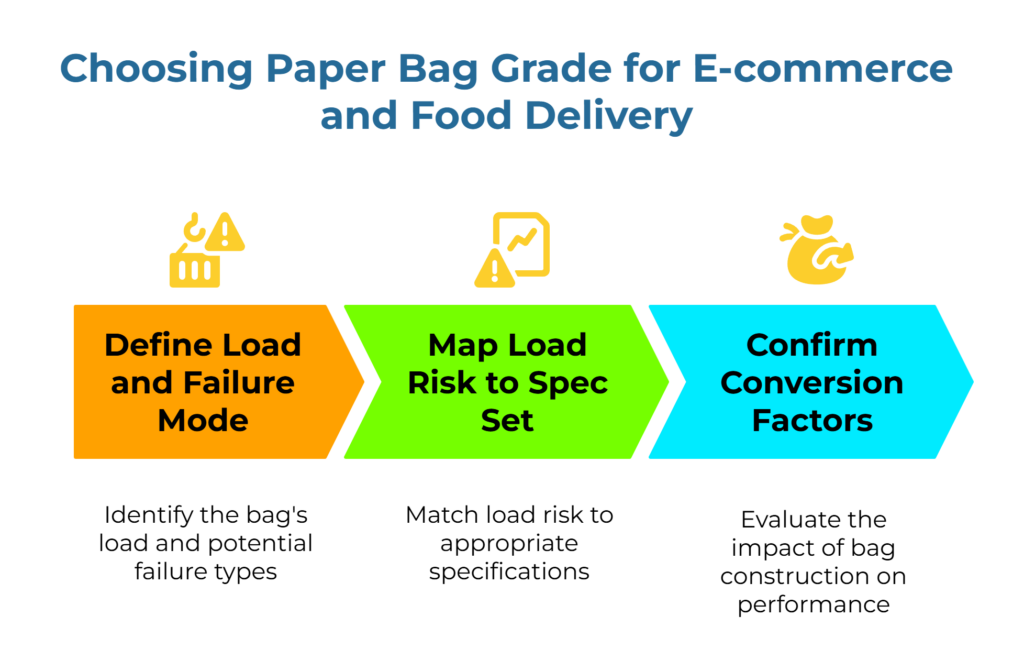

How to Choose a Bag Grade for E-commerce and Food Delivery

Step 1: Define Your Load and Failure Mode

Start with what the bag must survive, not with a GSM number. Different applications stress paper in different ways.

Rupture from internal pressure occurs when heavy or angular contents push against the bag walls. This is the failure mode burst strength predicts. Dense products, sharp edges, and overfilled bags increase rupture risk.

Tear propagation starts at a stress point, often a fold, handles attachment, or small nick, and spreads. Tear resistance relates more to tensile strength and fiber length than to burst strength.

Handle failure depends on handle construction, attachment method, and the paper’s ability to resist concentrated stress at the attachment points. Reinforced handles, twisted paper handles, and die-cut handles each have different failure patterns.

Wet weakening affects all paper but varies dramatically by grade. Standard untreated kraft paper can lose 90% or more of its tensile strength upon saturation. Wet-strength treated papers are chemically modified to retain typically 15% to 50% of their dry strength when saturated, depending on the wet-strength resin dosage. For food delivery where condensation or spills are likely, wet strength matters as much as dry burst values.

Identify which failure modes are most likely given your product mix, packaging process, and delivery conditions. Then specify those modes.

Step 2: Map Load Risk to a Minimal Spec Set

Use a three-band approach to match specifications to application risk. For deeper strategic guidance on matching kraft grades to specific bag applications, see kraft paper for making paper bags: a strategic guide to grade selection and procurement:

Light duty (small retail items, lightweight contents, dry conditions): Lower GSM range, moderate burst requirements, standard kraft sufficient. Typical load: under 2 kg, short carry distances, low moisture exposure.

Medium duty (typical e-commerce orders, mixed product weights, indoor delivery): Mid-range GSM, higher burst requirements, consider fiber source. Typical load: 2-5 kg, moderate handling stress, normal delivery conditions.

Heavy duty (dense products, outdoor exposure, stacking loads): Higher GSM range, elevated burst requirements, may require virgin kraft or wet-strength treatment. Typical load: over 5 kg, extended routes, higher failure cost.

For each band, the same spec framework applies:

- GSM with tolerance

- Burst requirement with method and unit

- Conditioning and testing requirement

- Sample approval tied to measurable criteria

The correct approach is to define your load scenario, request samples from potential suppliers, and test them under conditions that simulate actual use. Laboratory burst values establish baseline comparability. Real-world testing with your actual products confirms field performance.

Step 3: Confirm Conversion Factors

A paper bag is not a flat sheet. The conversion process, including bag construction, handle attachment, gusseting, folding, and glue lines, affects final performance. Two bags made from identical paper but constructed differently will perform differently.

When evaluating paper bags or paper bag suppliers, specify the paper properties you require, but also evaluate converter quality. Request finished bag samples alongside paper test reports.

The Spec-True Checklist: What to Put in Your RFQ

A specification that cannot be tested cannot be enforced. Before using the template below, understand what each field protects against:

Why Each Spec Field Matters

| Spec Field | Why It Matters | What to Write |

| GSM (g/m²) + tolerance | Prevents “GSM drift” and off-spec deliveries that affect cost and performance | “___ g/m² ± ___%, test method ISO 536 (or equivalent)” |

| Burst metric + unit | Prevents apples-to-oranges comparisons between suppliers using different metrics | “Bursting strength in kPa” or “Burst index in kPa·m²/g” |

| Test standard | Aligns lab method, apparatus, and reporting conventions across suppliers | “ISO 2758” (Global) or “TAPPI T403” (North America)” |

| Conditioning/ testing requirement | Paper properties vary with moisture; this ensures comparable results | “Report conditioning and test atmosphere; condition/test per ISO 187 (or agreed equivalent)” |

| Sampling/ acceptance | Makes QC enforceable and reduces receiving disputes | “Per batch/lot report, acceptance criteria as stated” |

| Change control | Prevents “silent substitutions” that compromise performance | “No spec-impacting changes without written approval” |

Copy-Paste RFQ Specification Template

PAPER BAG MATERIAL SPECIFICATION

1. Basis Weight (GSM)

Target: [X] g/m²

Tolerance: ± [Y]%

Test Method: ISO 536

2. Bursting Strength

Minimum: [X] kPa

Test Method: ISO 2758 (Global) or TAPPI T403 (North America)

3. Conditioning Requirements

All testing to be performed after conditioning per ISO 187

Standard atmosphere: 23°C ± 1°C, 50% ± 2% relative humidity

Minimum conditioning time: 4 hours

4. Sampling and Acceptance

Sample size: [X] samples per lot

Acceptance criteria: [Define AQL or pass/fail threshold]

5. Documentation Required

Certificate of Analysis (COA) for each shipment

COA must state: test date, test method, conditioning conditions, results

6. Additional Requirements (as applicable)

[ ] Wet strength treatment required

[ ] Fiber source: virgin / recycled / blend

[ ] Food contact compliance: [Specify standard]

Ultra-Compact Alternative Template

For teams preferring a condensed version:

PAPER BAG MATERIAL SPEC (COMPACT)

GSM: ___ g/m² ± ___ (method: ISO 536 or equivalent)

Burst: (kPa or kPa·m²/g) ≥ ___ (method: ISO 2758 / TAPPI T403)

Conditioning/testing: report conditioning and atmosphere; align to ISO 187 or equivalent

Sampling/acceptance: [Define criteria]

Change control: no spec-impacting changes without approval

The Spec-True mindset for measurable specs applies the same principles to moisture specifications using COBB values. The underlying approach is identical: name the property, state the target, define the tolerance, specify the test method, and require documentation.

Common Pitfalls That Cause Supplier Disputes

These five gaps cause most specification-related disputes between buyers and suppliers:

“Burst factor” quoted without units or method. A number without context is meaningless. If your supplier quotes burst factor and you quote burst index, you may be comparing incompatible values. Require explicit unit and method statements.

Burst values measured with different methods compared as if equal. An ISO result and a TAPPI result from the same sample may differ. If your specification says ISO and the supplier’s test report says TAPPI, you have a mismatch even if the numbers look similar.

No conditioning stated. Paper properties change with humidity. A test performed in Bangkok at 80% RH will differ from a test performed in Phoenix at 15% RH. Specify conditioning. Require compliance.

GSM tolerance missing. “80 GSM” is a target, not a specification. “80 GSM ± 3%” is a specification. Without tolerance, any result reasonably close to 80 becomes arguable.

Sample approvals not tied to measurable criteria. Approving a sample visually, then receiving production material that looks similar but tests differently, is a common failure. For systematic supplier approval processes, reference how to vet wholesale paper bag suppliers: a remote audit checklist. Tie approvals to test results, not appearance.

For Suppliers: How to Quote GSM and Burst Without Losing Buyer Trust

This section is for suppliers, mills, and converters who want to quote clearly and avoid post-delivery disputes.

Always include in your quotations and COAs:

- Test standard used (ISO 536 for GSM, ISO 2758 or TAPPI T403 for burst)

- Units for all values (g/m², kPa, kPa·m²/g)

- Conditioning conditions under which testing was performed

- Date of testing and batch/lot identification

Consider presenting both metrics: Provide bursting strength in kPa and burst index in kPa·m²/g. For buyers evaluating kraft paper for converting operations, see kraft paper grade guide for SME converters: choose the right grade for every job to understand how converters evaluate grade specifications. Buyers evaluating material efficiency will appreciate the normalized value. Buyers focused on absolute performance will use the kPa figure.

Be explicit about the “burst factor.” If you use this term, define it in your quote. State the formula, the units, and how it relates to your bursting strength and GSM values. Ambiguity here erodes trust faster than almost any other documentation gap.

Proactively address conditioning. If your facility operates in high-humidity conditions and your buyer operates in low-humidity conditions, results will differ. Acknowledge this. Offer to test under buyer-specified conditions or provide guidance on expected variation.

Clear documentation prevents disputes. Disputes cost more than the few extra minutes required to prepare a complete test report.

Quick Glossary Cheat Sheet

GSM (Grams per Square Meter): Basis weight measurement indicating mass per unit area. Higher GSM means heavier paper but not necessarily stronger paper. Test method: ISO 536.

Bursting Strength: Pressure in kilopascals (kPa) required to rupture a paper sample under standardized test conditions. Predicts resistance to internal pressure loads. Test method: ISO 2758 or TAPPI T403.

Burst Index: Bursting strength divided by GSM, expressed in kPa·m²/g. Normalizes strength by weight, allowing efficiency comparisons across different paper weights.

Burst Factor: Term used inconsistently across markets. May be equivalent to burst index or calculated differently. Always confirm formulas, units, and test methods when this term appears on a quote.

Conditioning: Process of exposing paper samples to controlled temperature and humidity before testing. Required for consistent, comparable results. Standard conditions per ISO 187[4]: 23°C, 50% RH.

Tolerance: Acceptable variation range around a target value. A specification of “80 g/m² ± 5%” accepts material testing between 76 and 84 g/m².

AQL (Acceptable Quality Level): Statistical sampling approach defining the maximum defect rate considered acceptable for a lot. Used in sampling plans to determine pass/fail decisions.

COA (Certificate of Analysis): Document provided by supplier stating test results for a specific shipment or lot. Should include test method, conditioning, date, and results. For guidance on interpreting lab reports, see how to interpret lab test reports for kraft paper: a procurement-friendly guide.

Frequently Asked Questions

Does higher GSM always mean a stronger bag?

No. GSM measures weight, not strength. Two papers at identical GSM can have very different burst values depending on fiber source, refining, formation, and additives. Always request burst test results alongside GSM specifications.

What is the difference between burst strength and burst factor?

Burst strength is a direct measurement in kPa from a standardized test. Burst factor is a derived value, but its calculation varies across markets and suppliers. Some use it interchangeably with burst index (burst strength ÷ GSM). Others calculate it differently. Always confirm the formula and units when the burst factor appears on a quote.

What unit should burst be quoted in?

Specify bursting strength in kilopascals (kPa) with the test method stated (typically ISO 2758 or TAPPI T403). This provides an absolute, comparable value. If you also want burst index for efficiency comparisons, request it in kPa·m²/g.

Why does humidity and conditioning matter?

Paper absorbs and releases moisture based on ambient conditions. Moisture affects both weight and strength. A sample tested at high humidity will weigh more and may test differently than the same sample tested at low humidity. Specifying conditioning per ISO 187 ensures all parties test under equivalent conditions.

How do I verify a supplier’s burst claims?

Request a Certificate of Analysis for each shipment. The COA should state the test method, conditioning conditions, and results. For critical applications, consider third-party testing of incoming material using the same method specified in your purchase order. For comprehensive quality verification frameworks, see COAs, samples, and incoming inspection: a simple evidence chain for packaging converter QA.

What if my supplier uses TAPPI and I specify ISO?

Results from different test methods are not directly comparable. If alignment is not possible, request that the supplier test a reference sample using your specified method so you can establish a correlation factor. Alternatively, agree on one standard and update your specification accordingly.

Next Steps

The gap between a failed bag and a reliable one is not a bigger budget or a better supplier. It is a clearer specification. Two practical actions to take from here:

First, request a sample and test report from your current or prospective suppliers. If you’re evaluating international suppliers remotely, use verifying international paper bags suppliers: a checklist for safe online sourcing as your verification framework. Ask for GSM, bursting strength in kPa per ISO 2758 or TAPPI T403, and documentation of conditioning. Compare what you receive against what was quoted. Gaps here signal gaps in production.

Second, standardize your RFQ template using the checklist in this guide. Every purchase order should state GSM with tolerance, burst requirement with method, and conditioning standard. This creates a paper trail that protects both parties and eliminates the most common sources of quality disputes.

If you are ready to evaluate options, you can find suppliers across the global paper industry or submit an RFQ to receive quotes from verified suppliers directly.

Disclaimer:

This guide provides general educational information about paper bag material specifications. It does not constitute professional engineering, quality assurance, or procurement advice. Specification requirements vary by application, jurisdiction, and operational context. Always consult qualified professionals and verify supplier capabilities through appropriate testing and documentation.

[1]: ISO 536 – Paper and board – Determination of grammage. International Organization for Standardization. https://www.iso.org/standard/77583.html

[2]: ISO 2758 – Paper – Determination of bursting strength. International Organization for Standardization. https://www.iso.org/standard/61487.html

[3]: Smithers – Understanding Bursting Strength in Paper and Board Testing.

[4]: ISO 187 – Paper, board and pulps – Standard atmosphere for conditioning and testing. International Organization for Standardization. https://www.iso.org/standard/80311.html

Our Editorial Process:

Our expert team uses AI tools to help organize and structure our initial drafts. Every piece is then extensively rewritten, fact-checked, and enriched with first-hand insights and experiences by expert humans on our Insights Team to ensure accuracy and clarity.

About the PaperIndex Insights Team:

The PaperIndex Insights Team is our dedicated engine for synthesizing complex topics into clear, helpful guides. While our content is thoroughly reviewed for clarity and accuracy, it is for informational purposes and should not replace professional advice.