📌 Key Takeaways

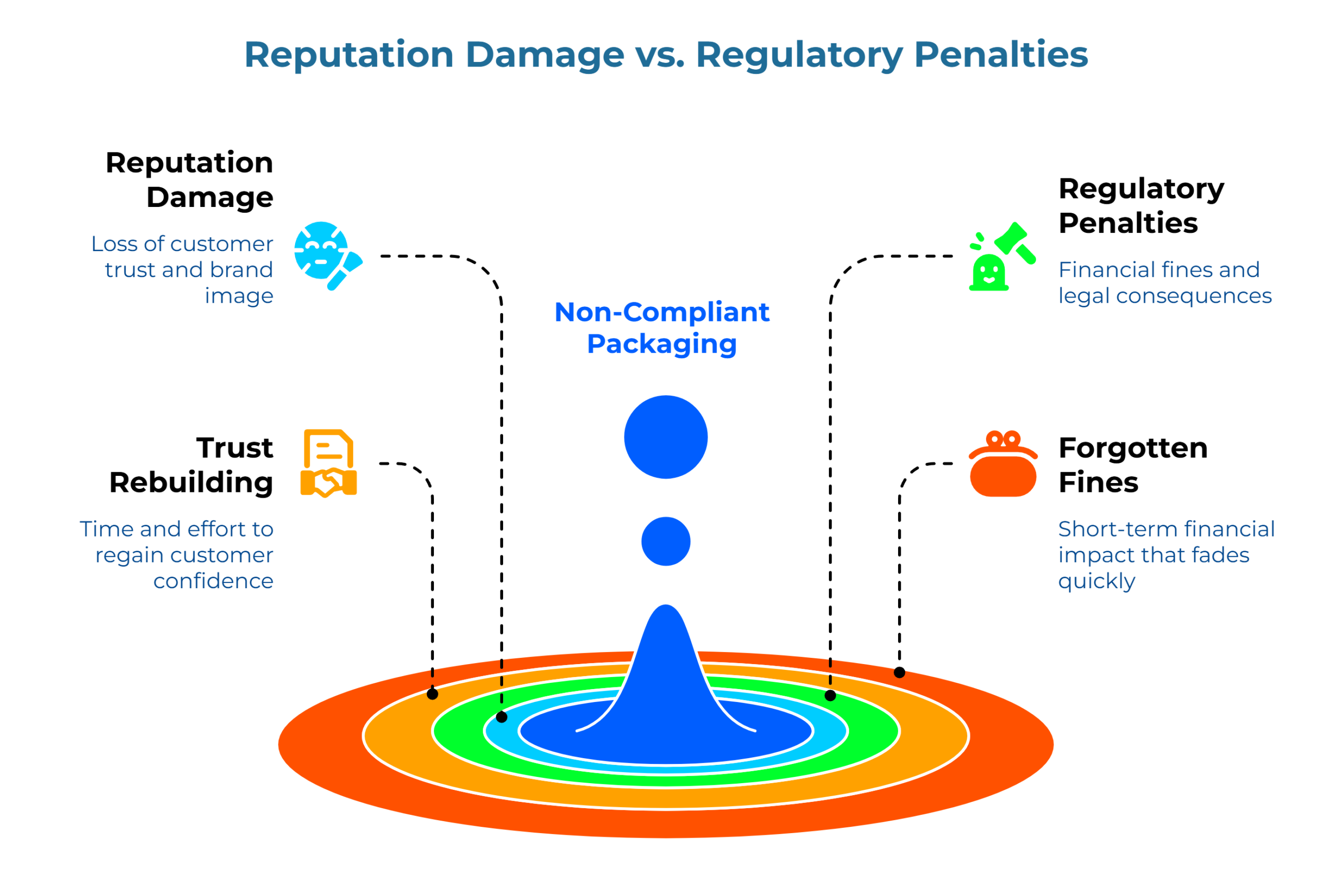

A packaging failure costs far more in lost trust than any fine—customers see grease stains as food safety problems.

- Fines Fade, Stories Stick: Regulatory penalties get paid in weeks, but negative reviews and lost customers can hurt for years.

- Three Paths to Public Trouble: Inspections, customer complaints, and supplier recalls all turn paperwork gaps into visible brand damage.

- “Food Safe” Means Nothing Without Proof: Verbal claims don’t count—you need certificates naming specific standards like FDA or EU regulations.

- Build One Audit-Ready Folder: Keep compliance documents, spec sheets, and invoice copies together so you can hand inspectors proof in minutes.

- Match Specs to Your Menu: Paper that works for dry pastries may fail with greasy fried foods—visible stains signal “dirty kitchen” to customers.

The fine is a line item; the reputation is the business.

Restaurant operators, food service managers, and procurement teams responsible for food packaging sourcing will find practical checklists and supplier verification templates here, preparing them for the detailed compliance framework that follows.

~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~

The health inspector closes their clipboard. They’ve asked for your food-contact packaging documentation.

You open the filing cabinet. Nothing.

That silence—the one where you realize you can’t prove your wrapping paper is safe for the burger it’s holding—costs more than any fine. The penalty goes on a form. The doubt goes into every customer interaction that follows.

Non-compliant food-contact packaging creates reputation damage that often exceeds the impact of regulatory penalties. A single visible incident can collapse customer trust in ways that take months to rebuild, while the fine itself gets paid and forgotten in weeks. Understanding where the real exposure sits makes it easier to build a clear-eyed case when someone suggests cutting corners on packaging spend.

Why a Compliance Miss Becomes a Reputation Incident

Packaging touches food. Customers see packaging. When something goes wrong—grease soaking through, ink transferring, an inspector asking uncomfortable questions—customers don’t think “packaging problem.” They think it is a “food safety problem.”

That mental leap happens instantly. A stained wrapper becomes a photo. The photo becomes a review. The review becomes the first thing a potential customer sees when searching your name online.

The budget conversation often frames compliance spending as pure defense: “We pay more to avoid fines.” That framing misses the larger picture. The goal isn’t just avoiding a penalty—it’s avoiding becoming a story. Fines have fixed costs. Stories have compounding costs: lost regulars, hesitant new customers, extra labor spent on damage control instead of service.

Many teams treat compliance as a checkbox that matters only if regulators show up. In practice, compliance failures behave more like public incidents because packaging is a frontline brand touchpoint. Customers see it, touch it, photograph it, and judge it—often faster than a business can respond.

The reputational risk also lingers. A fine (if it happens) may be a one-time event. Trust recovery is rarely one-time. It can require operational cleanup, customer communication, supplier changes, and weeks of heightened attention from staff—exactly when attention is already scarce.

The Three Ways Non-Compliant Packaging Turns Public

Packaging failures surface through three predictable channels:

The inspection or audit. An inspector asks for compliance documentation. The documentation is missing, or it doesn’t match what’s on the shelf. That gap becomes a finding. Findings become records. Records become discoverable. If the only evidence is “the supplier said it’s food safe,” the operation is exposed—because verbal claims do not travel well across inspections, management changes, or supplier substitutions.

The customer complaint. A diner notices oil bleeding through their takeout bag or ink on their sandwich wrap. They take a photo—because everyone takes photos now—and post it to a review platform with your name attached. Customers rarely describe packaging using regulatory language. They describe what they can see: staining, tearing, dampness, and transfer.

The supplier issue or recall. A supplier has a problem with a batch. Suddenly there’s inventory disposal, scrambling for replacement packaging, and explaining to customers why their usual order looks different. When a supplier issue forces a swap, a documentation gap becomes a speed problem. Without a ready proof set, the team spends time chasing certificates, matching invoice codes, and trying to reconstruct what was used. Meanwhile, inventory gets quarantined or discarded, and the business absorbs avoidable disruption.

Each channel amplifies the original problem. What started as a paperwork gap became a public trust question.

What “Non-Compliant” Actually Means in Food-Contact Paper

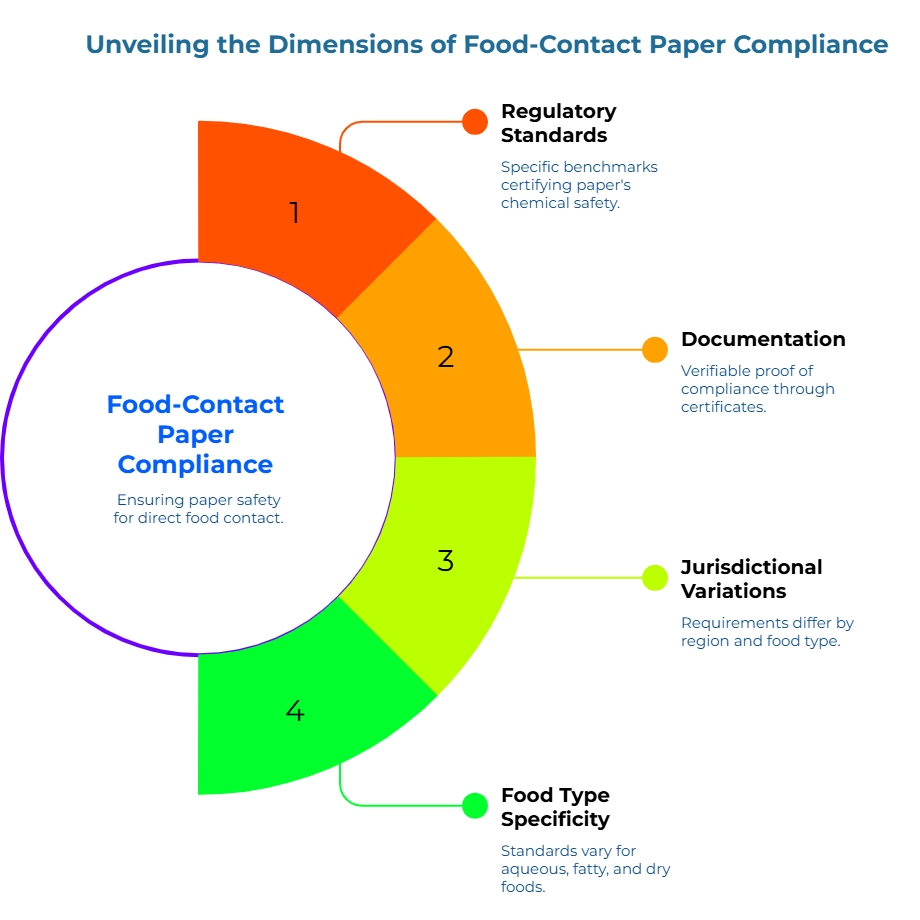

Food Contact Safety Standards are the specific regulatory benchmarks (like FDA or ISEGA) that certify a material is chemically safe for direct contact with consumable goods. Think of it as the “driver’s license” for the paper—proof it’s legally allowed on the road. Picture the peace of mind when handing the health inspector a single binder with all compliance certificates organized and valid.

A supplier saying ‘food safe’ isn’t proof—that phrase has no regulatory definition. What matters is documentation: a certificate citing specific standards, a test report from an accredited lab, a specification sheet with relevant codes, and basic traceability linking the paper on the shelf to those documents.

When importing packaging or facing a health inspection, verifiable proof is required—not a verbal claim. Suppliers may use vague terminology, and without certificates, compliance cannot be proven to inspectors or customers. For a deeper comparison of certification frameworks, see this guide on FDA vs. ISEGA requirements.

Requirements vary by jurisdiction and food type. The U.S. typically references FDA 21 CFR part-176.170 for aqueous and fatty foods, or FDA 21 CFR part-176.180 for dry foods. In Europe, while the EU operates under the Framework Regulation (EC) No 1935/2004, specific paper composition is often validated against national standards like the German BfR Recommendation XXXVI due to the lack of a harmonized EU paper regulation.[^2] Confirm applicable rules with local authorities.

Business Impact: Where the Real Costs Hide

Non-compliance costs tend to hide in operational friction and brand repair—not in a single penalty line item.

Direct costs are visible: disposal of non-compliant inventory, emergency reorders at premium prices, expedited shipping, reprinting branded materials, possible downtime while sourcing replacements.

Indirect costs hide deeper. Staff hours managing the crisis instead of serving customers. Service disruptions rippling through schedules. Menu packaging workarounds like double-wrapping, extra liners, and substitution chaos. Reviews that take months of consistent performance to overcome. Partner accounts—delivery platforms, catering clients—that quietly stop calling.

The reputation mechanics work against operators: customers interpret packaging failures as hygiene or ingredient safety issues, even when the actual risk is purely cosmetic. A grease stain on a bag doesn’t mean the food inside is unsafe. But customers don’t wait for explanations. When packaging becomes the visible sign of “something is wrong,” brand trust becomes the primary cost center.

Financial Impact Matrix: Exposure Assessment

When someone argues for cheaper, unverified packaging, numbers clarify the conversation. Use this template to map exposure with your own figures:

| Risk Trigger | Detection Point | Likelihood (L/M/H) | Immediate Actions | Direct Costs (USD) | Indirect Costs | Recovery Time |

| Missing compliance documentation | Health inspection | ___ | Produce proof or face citation | $___ fine + $___ consultant | ___ staff hours, service disruption | __ days |

| Visible wrapper failure (grease/ink) | Customer complaint or review | ___ | Replace order, respond publicly | $___ replacements + $___ rush shipping | ___ negative reviews, lost referrals | __ weeks |

| Supplier recall or batch issue | Receiving inspection or customer report | ___ | Dispose inventory, emergency reorder | $___ disposal + $___ expedited order | Menu disruption, partner confidence loss | __ weeks |

Illustrative example (not a verified claim): A batch disposal of $800 in packaging, plus $400 expedited replacement shipping, plus 12 staff hours at $18/hour managing the response, plus three negative reviews reducing new customer visits over the following month. The fine might be $250. The total exposure is multiples higher.

Fill in actual numbers for your operation. It clarifies what could happen, how it would be handled, and what the business would absorb.

How to Protect the Brand: Documentation Stack and Supplier Verification

Build one folder—physical or digital—containing the three documents you need to pass a health inspection. Keep it current. An audit-ready documentation stack reduces response time during incidents and helps protect brand trust under scrutiny.

Documents to Request from Suppliers

Keep these together in one folder per product and supplier:

- Certificate of compliance citing specific standards (FDA 21 CFR, EU 1935/2004, or equivalent)

- Test report from an accredited laboratory

- Product specification sheet with GSM, grease resistance rating, and coatings

- Invoice copies showing compliance codes and lot/batch numbers

- Supplier contact information and document validity dates

- Change notice process (how revisions are communicated)

For a structured approach to building this documentation system, The Compliance Shield: How to Audit Your Food Packaging Paper Suppliers for FDA & ISEGA Safety provides a step-by-step verification process.

Supplier Verification Email Template

Subject: Request for food-contact compliance documents – packaging paper

We’re updating our compliance records and need the following:

- Standard(s) your paper complies with (e.g., FDA 21 CFR part-176.170, EU 1935/2004)

- Supporting certificate or test report from accredited lab

- Product specification (GSM, grease resistance, coatings)

- Invoice code or lot number for traceability

- Document issue date and validity/revision date (and how changes are communicated)

Please send current documents at your earliest convenience.

How to spot vague answers: Responses like ‘It’s food grade’ or ‘All our products are safe’ without specific standard citations, certificate numbers, or lab names are red flags. A structured food contact compliance verification protocol can filter suppliers who cannot produce audit-grade evidence. Compliant suppliers can name the exact regulation and provide dated documentation.

Receiving Inspection Checks

Perform these lightweight, repeatable checks when packaging arrives:

- Product label matches the ordered item and specification

- Invoice includes identifiers that allow traceability (codes/lot info if used)

- No visible damage, discoloration, or unusual odor

- Visual and handling sanity check for obvious performance mismatch (tearing, transfer, seep-through)

- Store sample from each batch with dated label

For a quick quality check that can be performed at receiving, A Simple 5-Minute Grease Spot Test to Check Your Food Packaging Paper Supply provides a practical screening method.

Performance Specifications as Brand Protection

Performance specs protect reputation because they prevent visible failures that customers interpret as hygiene or quality issues.

GSM (basis weight) in plain language. GSM measures paper weight per square meter. Higher GSM typically indicates thicker, sturdier paper—often helpful for wraps and liners that face moisture, heat, or handling stress. GSM alone is not a safety certificate; it is a performance spec that determines whether paper holds up or tears during service.

Grease resistance in plain language. Grease resistance describes how well paper blocks oils and prevents seep-through. Low grease resistance can lead to staining, tearing, and transfer—exactly the cues that trigger complaints and photos.Together, GSM and Kit Levels determine whether oil soaks through onto hands and tables.

When specs don’t match the menu, failures become visible. Oil seep-through, tearing, ink smearing—these may not be safety issues, but customers read them as quality signals. A greasy bag suggests a greasy kitchen, even when it doesn’t.

Menu-mapping principles (illustrative):

- Light, dry items (bakery, sandwiches without sauce): Lower GSM, moderate grease resistance

- Oily items (fried foods, burgers with dressing): Higher GSM, high grease resistance (Kit Level 7+)

- Hot and wet items (steamed items, wrapped proteins): Moisture barrier plus grease resistance; focus on barrier behavior and structural integrity, not “thickness feel” alone

For operators sourcing internationally, Importing Food Packaging Paper? How to Verify International Safety Certifications covers how to validate documents from overseas food packaging paper suppliers.

Consensus Kit: Align Operators, Kitchen, and Procurement

This kit aligns stakeholders: the operator wants risk control, the kitchen wants performance, procurement wants repeatable sourcing.

Comparison Table: Unverified vs. Verified Packaging

| Dimension | Unverified Packaging | Verified, Fit-for-Purpose Packaging |

| Compliance proof | “Food safe” claim without documents | Documents tied to product + invoice/PO trail |

| Inspection readiness | Slow, reactive scrambling | Fast retrieval from an audit-ready folder |

| Customer perception | Higher risk of visible failures read as quality/hygiene issues | Lower risk of stain/tear/transfer signals; consistent presentation builds trust |

| Operational friction | Workarounds (double-wrap, substitutions) | Specs matched to menu; consistent service behavior |

| Incident response time | Longer (reconstruct what was used) | Shorter (traceable, documented) |

Documentation and Receiving Checklist

Documents to request from suppliers:

- Certificate of compliance citing specific standard (FDA, EU, or equivalent)

- Lab test report from accredited source

- Specification sheet (GSM, grease resistance/Kit Level, coatings, dimensions)

- Invoice template showing how compliance codes and lot numbers appear

- Document validity date; set calendar reminder for annual refresh

- Change notice process (how revisions are communicated)

Receiving inspection checks:

- Packaging matches specification sheet (weight, coating, size)

- No visible damage, discoloration, or unusual odor

- Lot number on delivery matches supplier documentation

- Store sample from each batch with dated label

Storage (audit-ready, low-effort):

- One folder per product + supplier

- Save: spec sheet, proof docs, most recent invoice

- Add a simple “last verified” date and a supplier contact

FAQ: Questions That Prevent Surprises

If a supplier says “FDA compliant,” what should the paperwork actually show?

Look for a certificate or letter citing the specific FDA regulation (e.g., 21 CFR part-176.170 for paper and paperboard). For a complete verification approach, use these seven questions to ask a new supplier that unverified vendors cannot answer. A test report from an accredited lab adds credibility. “FDA compliant” as a phrase alone, without documentation, isn’t verifiable proof.

How often should compliance documents be refreshed?

Request updated documents annually, or whenever the supplier changes materials, coatings, inks, or manufacturing sites — compliance decay happens when documentation lags behind process changes. Set a calendar reminder. Expired or outdated documents are nearly as problematic as missing ones during an inspection.

What changes should trigger a compliance re-check?

Any change in ink, coating, paper supplier, or manufacturing location. Also: adding new menu items with different grease or moisture profiles warrants confirming existing packaging still matches the job.

Is a thicker paper automatically safer?

No. Thickness relates to performance and handling. Safety for food-contact is demonstrated through applicable standards, documentation, and fit-for-use decisions. A thick paper without proper certification is no safer than a thin paper without certification.

Can the same paper work for different menu items?

Sometimes, but mismatches create visible failures. A wrapper that handles dry pastries may fail with oily fried items. Matching food grade packaging paper selection criteria to actual menu use prevents customer-facing problems.

What is ISEGA in simple terms?

ISEGA is an organization known for testing and assessment related to food-contact materials. It is often referenced in supplier documentation, particularly in European markets, as a trusted third-party verification body.

Where can operators find pre-vetted suppliers with compliance documentation?

The PaperIndex supplier directory connects buyers with food packaging paper suppliers and mills globally. Requesting documentation upfront—using the email template above—filters for suppliers who can provide proper proof.

Treat Compliance as a Brand Asset

Verified compliance isn’t just defensive spending. It functions as a trust signal. When an inspector asks for documentation and receives a complete, current folder, that confidence shows. When customers see consistent, professional packaging that performs as expected, that consistency registers—even if they never articulate it.

A calm, repeatable proof layer—documentation tied to product, tied to purchase records—reduces incident response time and prevents avoidable public moments. Pair that proof layer with fit-for-purpose specs (GSM and grease resistance), and packaging stops being a hidden risk. It becomes a quiet signal of professionalism.

The practical next step: build a one-page specification sheet covering the packaging needs for each menu category. Use it to request documentation from current and prospective suppliers. Keep everything in one folder, refreshed annually.

For additional frameworks on balancing certification requirements with performance specifications, Food Packaging Paper Sourcing Matrix: Balancing Safety Certification with Performance Specs provides a structured approach.

The fine is a line item. The reputation is the business.

Disclaimer:

This article is for general informational purposes only and does not constitute legal or regulatory advice. Food-contact packaging requirements vary by jurisdiction; confirm applicable rules with your local authority and qualified professionals.

Our Editorial Process:

Our expert team uses AI tools to help organize and structure our initial drafts. Every piece is then extensively rewritten, fact-checked, and enriched with first-hand insights and experiences by expert humans on our Insights Team to ensure accuracy and clarity.

About the PaperIndex Insights Team:

The PaperIndex Insights Team is our dedicated engine for synthesizing complex topics into clear, helpful guides. While our content is thoroughly reviewed for clarity and accuracy, it is for informational purposes and should not replace professional advice.