📌 Key Takeaways

ECT specifications prevent compression failures in electronics packaging, while bursting strength addresses puncture risks—choose based on your dominant distribution stress.

- ECT for Stacking Dominance: Palletized, warehoused, and containerized electronics shipments require ECT specifications because compression causes far more failures than punctures.

- Humidity Erodes Board Strength: A box rated at 7.0 kN/m under laboratory conditions may perform closer to 5.5 kN/m after extended humid transit, making moisture assumptions non-negotiable.

- Specification Ambiguity Creates Quote Chaos: ECT numbers without test methods, units, board construction, and conditioning parameters produce incomparable supplier quotes and post-award disputes.

- BCT Validates Real-World Performance: Box Compression Tests on finished boxes confirm that board-level ECT specifications translate to acceptable stacking performance under actual warehouse conditions.

- Bursting Strength Solves Different Problems: Add burst requirements only when puncture or rough-handling damage dominates your documented failure patterns—it won’t prevent compression collapse.

Comparable specifications require aligned test methods, units, flute profiles, and moisture assumptions—not just strength numbers.

Packaging engineers and procurement managers sourcing corrugated boxes for consumer electronics will gain specification clarity here, preparing them for the detailed implementation frameworks that follow.

The damage report lands on your desk, and the box that was supposed to protect a $400 wireless speaker failed somewhere between the warehouse and the customer’s door. Crushed corners. Diagonal crease lines. The spec sheet promised “high burst strength.” So what went wrong?

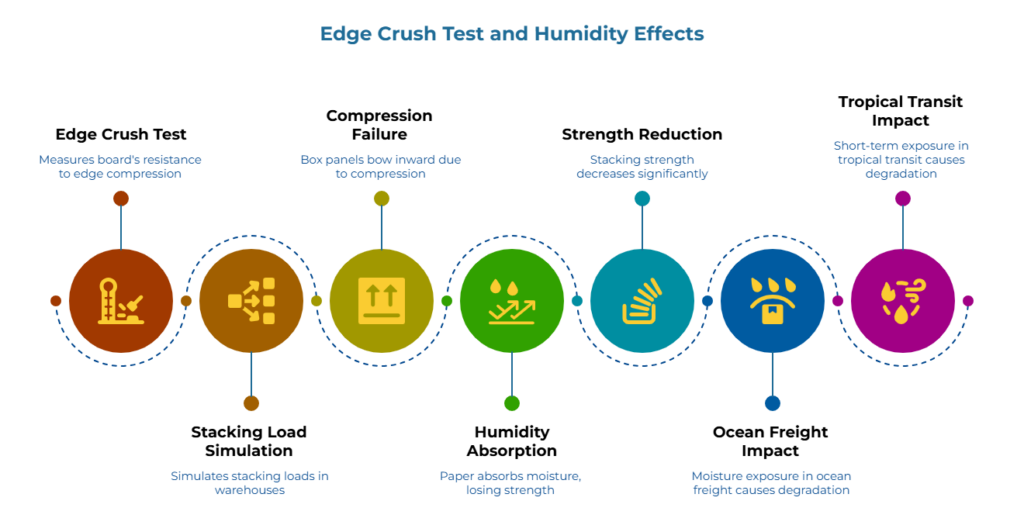

This scenario plays out regularly for procurement managers and packaging engineers shipping consumer electronics. Two strength metrics dominate supplier quotes—Edge Crush Test (ECT) and bursting strength—but they measure fundamentally different failure modes—but they measure fundamentally different failure modes.

For most consumer electronics distribution, ECT should be your primary specification because stacking and compression forces cause far more box failures than punctures or ruptures. That high burst rating won’t help when pallets stack six high in a humid warehouse for three weeks.

The Quick Decision for Electronics

If your boxes will be palletized, stacked in warehouses, or shipped in containers, lead with ECT. This metric predicts the edgewise compressive strength of the board, which is the primary determinant of a finished box’s Box Compression Test (BCT) value. In palletized electronics distribution, where top-to-bottom compression is the primary stressor, ECT-based specifications help prevent column collapse and creep rupture. However, it is important to note that while ECT measures the material, the McKee formula is typically required to estimate how that material will perform as a finished structure.

Incorporate bursting strength as a secondary metric when puncture and rough handling represent significant risks: individual parcel shipments, products with sharp internal components, or lanes with known strapping damage issues.

For high-stakes shipments, validate specifications with Box Compression Test (BCT) results on finished boxes or drop-test data that reflects your actual distribution environment.

One point that procurement teams frequently overlook: an ECT number without the test method, units, board construction, and moisture assumptions is not a specification. When sourcing corrugated boxes, this specification discipline prevents costly misunderstandings and enables true supplier comparability. It’s a guess that makes supplier quotes impossible to compare meaningfully.

What ECT Measures and Why It Matters

The Edge Crush Test measures how much force corrugated board can withstand when compressed on its edge—the same direction as stacking loads in a warehouse or container. Results are expressed in pounds per lineal inch (lb/in) or kilonewtons per meter (kN/m).

This metric correlates to stacking performance, estimating the maximum load localized to the box perimeter before vertical failure. When electronics shipments fail during transit, the typical signature is vertical crease lines and panels bowing inward. That’s compression failure, not puncture.

Humidity complicates matters significantly. Paper is hygroscopic and loses significant structural integrity as it absorbs moisture. A box rated at 7.0 kN/m under standard laboratory conditions (23°C, 50% relative humidity per TAPPI T 402) may see a reduction in stacking strength of 40–60% when relative humidity reaches 90%. This degradation is particularly critical for ocean freight and long-distance container shipping, where moisture exposure compounds over weeks. This degradation is non-linear; even short-term exposure to high-humidity tropical transit or ocean freight can cause a corrugated container to lose over half its rated compression strength before reaching its destination. A “dry lab” number can create dangerous overconfidence for ocean freight or shipments through tropical climates.

What Bursting Strength Measures and When It Helps

Bursting strength measures resistance to rupture—tested by pushing a rubber diaphragm against the board surface until breakthrough occurs. Results appear in kilopascals (kPa) or pounds per square inch.

This metric indicates the board’s tensile strength and resistance to internal or external hydraulic-like pressures: survival against sharp impacts, forklift tine contact, corner strikes, or strapping that cuts into the surface. For distribution channels where rough handling dominates, bursting strength matters.

The limitation becomes clear when you consider the physics involved. A board can have excellent burst resistance while still collapsing under moderate stacking loads. Thick, dense liners resist puncture effectively, but the fluted medium beneath may buckle under vertical compression. For electronics moving through palletized distribution, prioritizing burst over ECT addresses the wrong failure mode entirely.

Match the Specification to Your Shipping Mode

Distribution channels create different stress profiles, and specifications should reflect those realities.

Parcel and individual shipments expose boxes to drops, conveyor impacts, and handler tosses—stress profiles that differ fundamentally from palletized distribution where stacking loads dominate. Puncture and corner-crush risks increase relative to palletized freight. ECT still matters for structural integrity, but bursting strength becomes more relevant. Evaluate both metrics for this channel.

Palletized LTL and full truckload shipments place stacking at the center of the stress profile. Boxes sit under other boxes for extended periods—sometimes six high for three weeks in a humid warehouse—accumulating compression fatigue. ECT serves as the primary metric here, and requesting BCT data on finished boxes provides validation that the specification translates to real-world performance.

Ocean freight and long-distance container shipping combines stacking loads with humidity exposure. Specify ECT with explicit moisture assumptions, either by requesting testing at elevated humidity or by building a safety factor into minimum requirements. The combination of time, temperature cycling, and moisture accumulation can reduce board strength substantially.

ECT vs. Bursting Strength: Comparison for Electronics

| Aspect | ECT (Edge Crush Test) | Bursting Strength |

| What it measures | Edgewise compression resistance | Rupture resistance under pressure |

| Real-world prediction | Stacking strength and column stability | Puncture survival and rough-handling tolerance |

| Where it fails to predict | Puncture and impact damage | Compression and stacking failure |

| Primary electronics application | Palletized, warehoused, and containerized shipments | Parcel shipments with drop/puncture exposure |

| Specification elements | Value in kN/m, referencing established test methods such as TAPPI T 811, TAPPI T 839, or ISO 3037. Ensure the specification clarifies which method is used, as ‘waxed edge’ (T 811) vs. ‘unwaxed edge’ (T 839) can yield varying results for the same board grade | Value in kPa, test method (TAPPI T 810), liner weight |

For consumer electronics distribution, ECT is the primary metric. Add bursting strength requirements only when puncture risk is a documented concern for your specific distribution channel.

How to Write a Comparable Specification

Supplier quotes become comparable only when specifications define the same parameters. Include these elements in corrugated box sourcing requests:

Box configuration: Style (RSC, die-cut, etc.), internal dimensions in millimeters, and closure method. Aligning procurement and engineering teams on these parameters before RFQs are issued prevents the 23% quote spreads that emerge from specification ambiguity.

Board construction: Flute profile (B, C, BC double-wall, etc.) and wall configuration. A 7.0 kN/m specification on C-flute single-wall performs very differently than the same number on BC-flute double-wall.

Strength requirements: Minimum ECT value with units, referencing the applicable test method standard. Include tolerance ranges and specify whether the requirement applies to incoming board or finished boxes.

Environmental assumptions: Conditioning parameters for testing (temperature and relative humidity) or explicit acknowledgment that results reflect standard laboratory conditions. For humidity-sensitive lanes, specify testing conditions that approximate actual transit environments.

Verification protocol: Sampling frequency, acceptable quality limits, and documentation requirements. When verifying overseas suppliers, these protocols become especially critical as geographic distance amplifies the risk of specification drift. Request recent test reports or Certificates of Analysis, and clarify whether reported values represent board-level or finished-box testing.

Board-level ECT doesn’t account for box construction quality. Glue joints, flap alignment, and die-cut accuracy all affect how laboratory board strength translates to finished-box performance.

Common Pitfalls and How to Avoid Them

Specifying ECT without board construction creates incomparable quotes. The same ECT value performs differently across flute profiles and wall configurations—a technical detail that fundamentally changes box performance. Always include a board construction line item that specifies flute type and wall count.

Using burst to solve a stacking problem mismatches the metric to the failure mode. This specification error illustrates why ‘cheap’ boxes often cost more when damage rates rise—the unit price savings disappear into replacement, reshipping, and return costs. When damage reports show vertical creases and inward-bowing panels, the root cause is compression—not puncture. Address this with appropriate ECT specifications and proper stacking patterns, not higher burst ratings.

Assuming the specification alone prevents breakage overlooks the role of internal protection. Board strength functions like armor, protecting the box structure from external forces. But fragile electronics also need internal cushioning—the ‘airbags’ that absorb shock and vibration. Integrating high-spec cushioning into sourcing contracts closes the accountability gaps that emerge when box and cushioning are sourced separately. A correctly specified box won’t protect products if internal fit and cushioning are inadequate. These are complementary protection layers, not substitutes.

Frequently Asked Questions

Is ECT always the right primary metric for electronics?

For palletized, warehoused, or containerized distribution—yes. Stacking and compression dominate the failure profile for these channels. For individual parcel shipments with significant drop and puncture exposure, evaluate both ECT and bursting strength based on documented damage patterns.

What distinguishes ECT from BCT?

ECT tests the board material itself under edgewise compression. BCT (Box Compression Test) tests finished boxes under stacking load, measuring how much force the complete box can withstand before buckling or collapsing. BCT provides real-world validation but requires finished samples and reflects a specific box design. Use ECT for material specification during sourcing; use BCT to validate that your specifications and box design translate to acceptable finished-box performance under actual stacking conditions.

Can suppliers manipulate test results?

Testing under ideal conditions, selective sampling, or reporting board values against box specifications can all create misleading impressions. Request complete test method details including conditioning parameters. Clarify whether results represent board or finished boxes. For critical applications, consider independent verification testing.

Do double-wall boxes change the recommendation?

Double-wall construction improves both ECT and burst performance, but ECT remains the primary metric for stacking applications. The additional wall increases compression resistance—exactly the property that electronics distribution demands. For operations managers selecting specifications, understanding how basis weight and caliper trade-offs affect converting equipment becomes critical when double-wall boards are specified, as the increased caliper can affect machine nip gaps and die clearances.

How should ocean freight or high-humidity lanes affect the specification?

Build moisture-related strength loss into your safety margin. If domestic trucking requires 7.0 kN/m, consider specifying 8.5–9.0 kN/m for ocean freight to account for humidity exposure. Alternatively, request testing under elevated humidity conditions that approximate your shipping environment rather than relying on standard dry-lab results.

Resources

PaperIndex Guides

- Understanding Corrugated Box Flute & Wall Types

- How Containerboard ECT/RCT/SCT Translate to Real-World Box Strength

- The Total Protection Strategy: Integrating High-Spec Cushioning into Your Sourcing Contracts

- The ‘Relay Baton’ Test for Chain-of-Custody Verification

- Seven Questions to Ask a New Supplier (That Scammers Can’t Answer)

Other Resources

Moving Forward with Specification Discipline

Corrugated box sourcing for electronics becomes more predictable when specifications align with actual distribution stresses. ECT provides the foundation for stacking-dominated channels. Bursting strength adds value for puncture-prone applications. Neither metric works in isolation—comparable quotes require aligned test methods, units, board construction details, and moisture assumptions.

For a deeper understanding of how containerboard test terminology translates to practical box performance, the guide on ECT, RCT, and SCT interpretation provides the technical foundation. When internal protection is critical, The Total Protection Strategy covers how to integrate cushioning specifications into sourcing contracts.

Disclaimer:

This content is for educational and informational purposes only. Testing requirements and performance standards vary by application, product characteristics, and distribution environment. Consult qualified packaging professionals for specification decisions involving high-value or damage-sensitive shipments.

Our Editorial Process:

Our expert team uses AI tools to help organize and structure our initial drafts. Every piece is then extensively rewritten, fact-checked, and enriched with first-hand insights and experiences by expert humans on our Insights Team to ensure accuracy and clarity.

About the PaperIndex Insights Team:

The PaperIndex Insights Team is our dedicated engine for synthesizing complex topics into clear, helpful guides. While our content is thoroughly reviewed for clarity and accuracy, it is for informational purposes and should not replace professional advice.